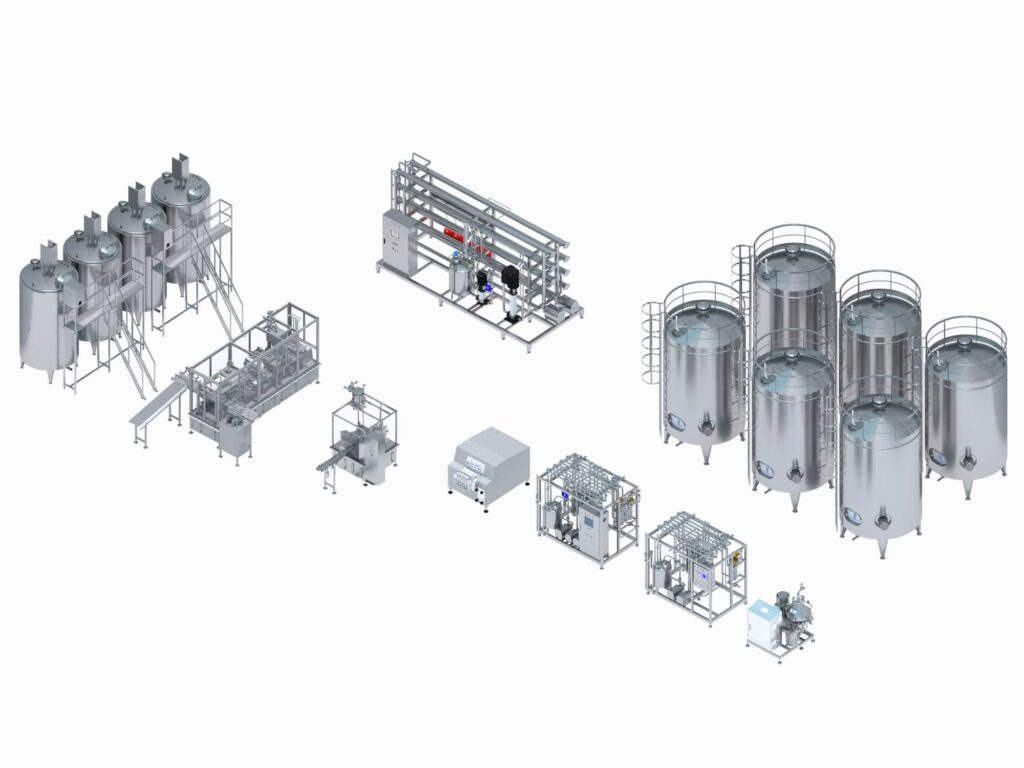

Yogurt Production Line With UF Membrane Filtration

A next-generation yogurt processing solution designed to deliver higher protein, lower whey waste, and premium consistency.

Innovative UF-Based Yogurt Processing Technology

ProTrus’ yogurt production line with UF (Ultrafiltration) membrane technology enables dairy manufacturers to produce high-protein, spoonable, and drinkable yogurt varieties with minimal whey separation.

Unlike traditional methods where part of the valuable solids are lost, UF membranes retain proteins and fat molecules while filtering out excess water and lactose. The result is a concentrated, creamy yogurt base that requires less added milk powder and delivers longer shelf life. This technology is particularly advantageous for Greek-style yogurt, labneh, high-protein drinkable yogurts, and export products.

Customised Line Design and Integrated Automation

ProTrus designs fully automated UF yogurt lines tailored to your production needs. The system integrates key modules including milk standardisation, pre-heating, fermentation tanks, ultrafiltration units, and automatic filling. Our PLC-controlled architecture ensures seamless flow control, accurate Brix or protein targets, and real-time CIP monitoring.

Looking to expand your yogurt range or improve yield? Contact our team today for a custom-engineered solution built around efficiency, hygiene, and output quality.

Contact Form

ProTrus Advantage in Yogurt UF Systems

UF technology from ProTrus is trusted by industrial yogurt producers for its ability to deliver:

What Is UF Membrane Filtration in Yogurt Production?

Ultrafiltration (UF) is a membrane separation technique that removes water and small dissolved solids from milk, while retaining proteins and fats. This results in a more concentrated yogurt mix with enhanced nutritional and textural properties.

Key Stages in UF Yogurt Processing

- Milk Standardisation: Initial adjustment of fat and SNF levels.

- Pasteurisation & Homogenisation: Ensures safety and emulsion stability.

- UF Concentration: Removes water and lactose while concentrating proteins.

- Fermentation: Controlled incubation to develop acidity and texture.

- Filling & Cooling: Done under hygienic conditions to preserve shelf life.

UF Yogurt Applications

- Spoonable Greek-style yogurt

- Drinkable protein-enriched yogurt

- Labneh and strained yogurts

- Export-ready long shelf-life dairy

Regulatory and Process Benefits

UF yogurt complies with clean-label trends as it allows natural protein enrichment without additives. It also reduces whey disposal needs and supports eco-friendly operations with reduced water load in effluents.

Ready to upgrade your yogurt production with UF technology? Get in touch with ProTrus today for a turnkey yogurt line that delivers premium taste, texture and yield.

Get in Touch Today

Get in touch today to explore how our dairy processing solutions can elevate your production efficiency and product quality.