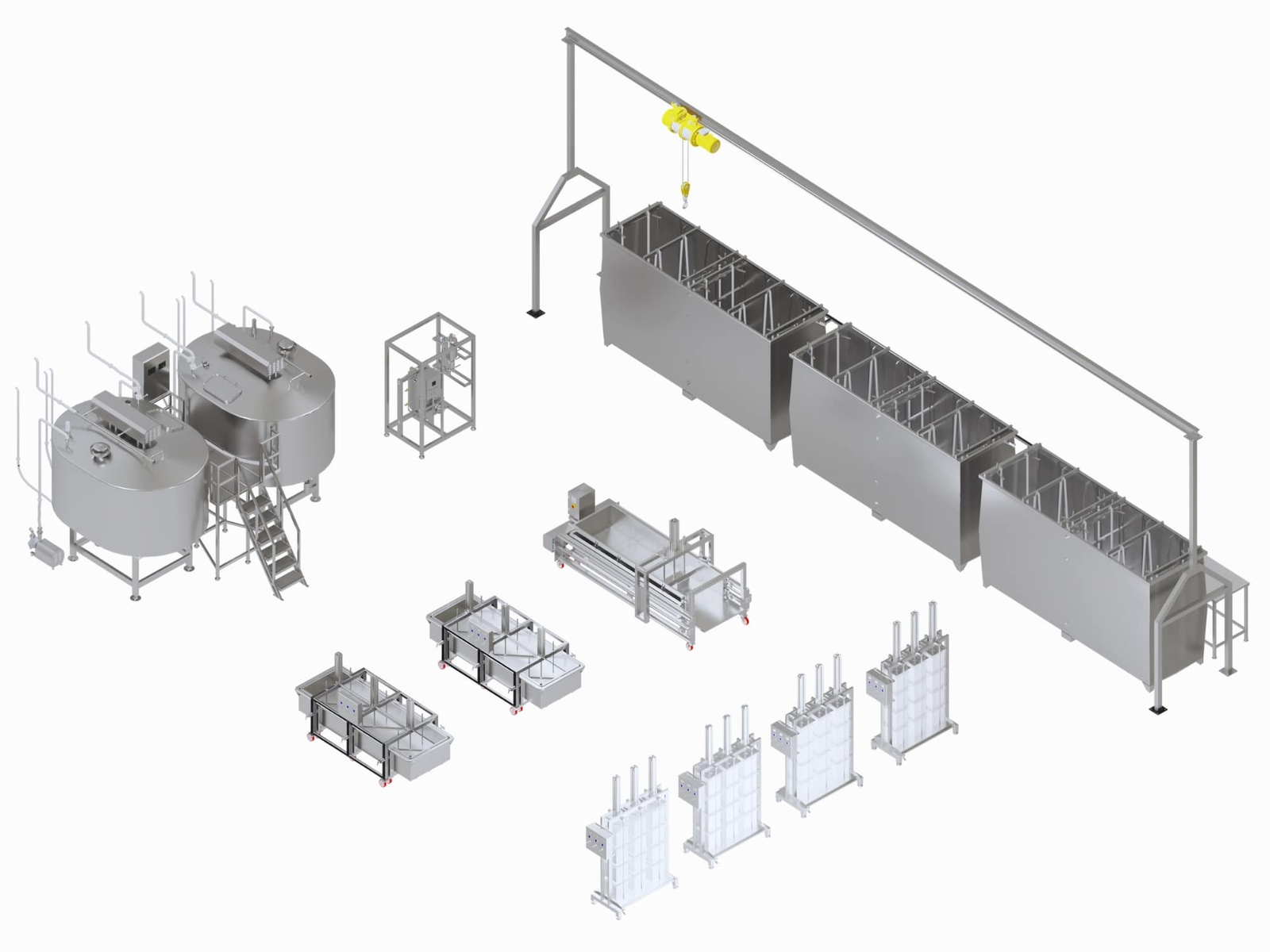

Filtered and Combi Cheese Production Line

Experience seamless integration of filtration and combining processes in one automated production line tailored for diverse cheese varieties.

Key Features

Our Filtered and Combi Cheese Production Line combines ultrafiltration, diafiltration, and cream blending in a single, space-saving configuration. Each module is crafted from food-grade stainless steel with CIP capabilities, ensuring rapid cleaning and minimal downtime.

Advanced SCADA integration provides real-time monitoring of flow rates, pressures, and temperature profiles—guaranteeing consistent yield and quality batch after batch.

The combi section seamlessly merges filtered milk or whey concentrates with natural cultures, salt, and enzymes. Precise dosing pumps and high-accuracy flowmeters ensure each cheese type—from Cheddar to Gouda—meets exact recipe specifications, reducing waste and manual intervention.

Turnkey Solutions & Support

ProTrus delivers end-to-end project management: from feasibility studies and 3D plant layouts to on-site installation and operator training.

A contact form is available alongside this section—request your personalized quote today!

Contact Form

Advanced Automation & Monitoring

Our system’s PLC controls and HMI interfaces enable recipe management, batch traceability, and remote diagnostics. Gain full production visibility and rapid fault detection to maximize uptime.

Scalable Design

Whether you’re launching a boutique dairy or expanding an industrial plant, our line scales from 1,000 L to 50,000 L per hour. Modular skid-mounted units simplify integration into existing facilities.

Hygienic Process Control

All fluid pathways maintain a 3A sanitary design. Automated valve sequencing and spray-ball CIP systems eliminate cross-contamination risks, ensuring compliance with FDA and EU standards.

Energy Efficiency

Optimized heat exchangers and variable-frequency drive (VFD) pumps reduce power consumption by up to 30%. Heat recovery loops pre-heat incoming milk, cutting steam costs and CO₂ emissions.

Customized Cheese Varieties

From high-moisture cream cheeses to aged semi-hard wheels, recipe flexibility allows you to produce multiple lines on a single footprint. Quick-change scraper and hoop mechanisms minimize changeover times.

Global Compliance & Quality

All equipment is CE-marked and built under ISO 9001 guidelines. Our international service network supports you with spare parts, regulatory updates, and predictive maintenance programs.

Ready to elevate your cheese production? Contact ProTrus today to design your bespoke Filtered and Combi Cheese Production Line—optimizing yield, quality, and efficiency across every batch.

Get in Touch Today

Get in touch today to explore how our dairy processing solutions can elevate your production efficiency and product quality.