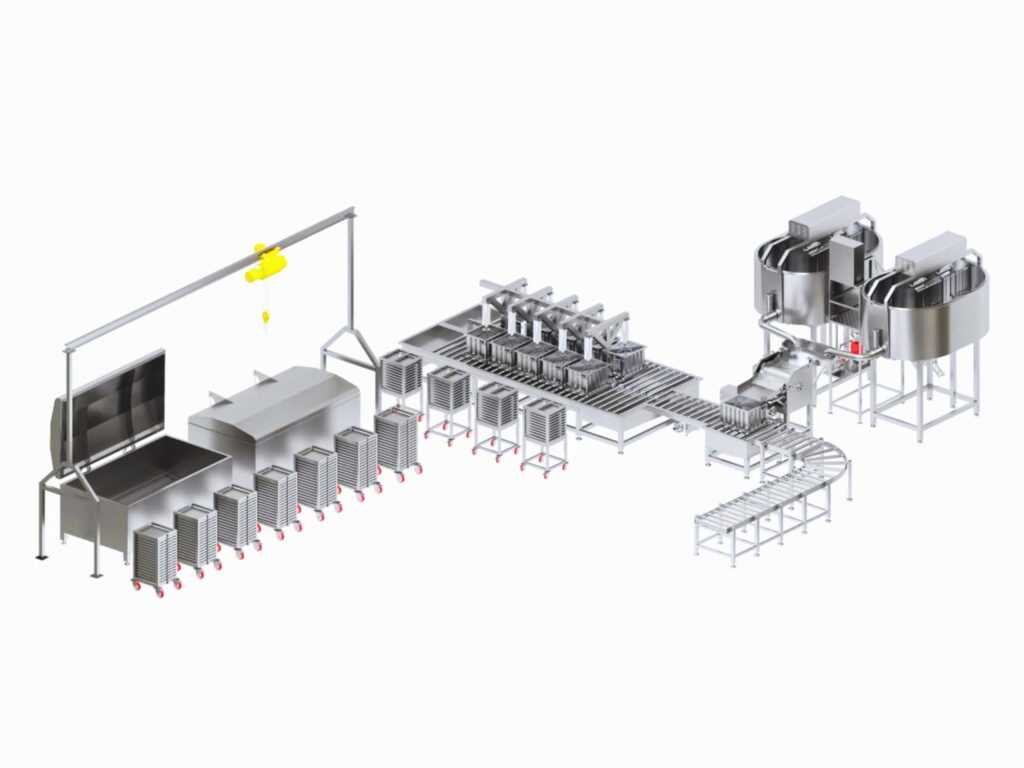

Halloumi Cheese Production Line

Produce consistent, high-quality Halloumi with ProTrus’s automated and hygienic systems.

Optimized for Traditional Halloumi Characteristics

Halloumi cheese requires unique processing stages, including curd pressing, folding, and brining. ProTrus designs production lines that preserve traditional texture while increasing output and ensuring full compliance with international hygiene standards. Every step—from milk standardization and coagulation to final packaging—is fully integrated and automation-ready.

Designed for Efficiency and Safety

Our Halloumi cheese line is engineered for:

Continuous curd processing and folding

High-efficiency pressing and cooling stations

Precise salting and brining controls

The entire system features CIP-compatible surfaces and is compliant with CE and ISO 9001 certifications—reinforcing ProTrus’s commitment to hygiene and global manufacturing standards.

Contact Form

Engineered for Expansion and Customization

Every dairy facility has its own operational needs. That’s why ProTrus offers modular Halloumi production systems that can be scaled up as demand grows. Whether you’re looking to serve domestic markets or export Halloumi to the EU, Gulf countries, or North Africa, our systems are designed with flexibility and compliance in mind.

Contact us today to explore a tailor-made solution that fits your production goals and regulatory requirements.

Advanced Section: Strategic Insights for Long-Term Value

To stay competitive in the dairy sector, producers must deliver traditional flavor while meeting modern expectations for consistency, safety, and sustainability. Halloumi, with its semi-hard texture and high melting point, is not only a cultural staple in the Mediterranean but also a high-margin product in global markets.

Why Choose ProTrus for Your Halloumi Production Line?

- Consistency at Scale: Our proprietary folding and brining modules simulate the traditional hand-folding process while supporting continuous output.

- Smart Integration: SCADA and PLC systems provide live batch tracking, pH/moisture monitoring, and recipe management, ensuring real-time control and traceability.

- Minimal Downtime: High-quality components and CIP integration reduce cleaning time and unplanned maintenance.

- Sustainable Design: Energy-efficient pasteurizers, optimized water circulation, and heat recovery systems minimize resource consumption.

Export-Ready Compliance

ProTrus equipment complies with FDA, EFSA, and GCC standards. Whether your goal is supermarket-grade packaging or bulk delivery for food service, our line is capable of producing Halloumi in various formats: plain, mint-infused, vacuum-packed, or MAP-sealed.

Support Beyond Delivery

We don’t stop at installation. Our after-sales network spans five continents. ProTrus ensures your plant continues to operate at peak performance through preventive maintenance, remote diagnostics, and on-demand technical support.

Get in Touch Today

Get in touch today to explore how our dairy processing solutions can elevate your production efficiency and product quality.