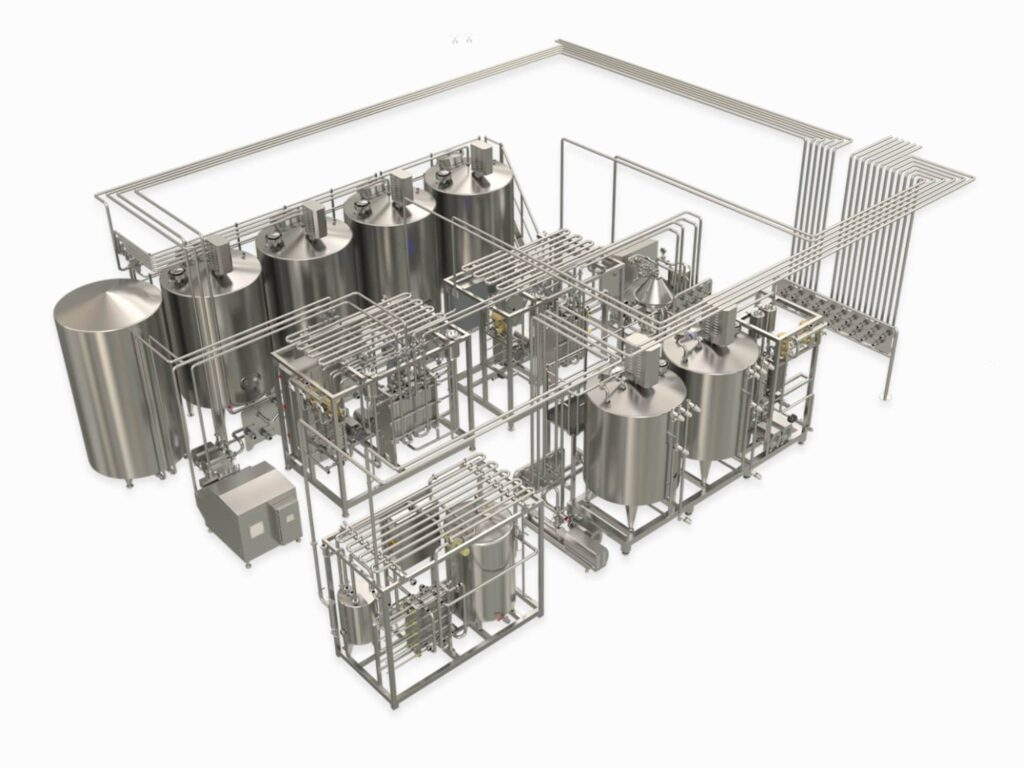

Pasteurization and Standardization Line

ProTrus offers a cutting-edge pasteurization and standardization line designed to optimize dairy processing efficiency and product consistency.

Advanced Dairy Processing Solutions

Our pasteurization and standardization line integrates seamlessly into your dairy operations, ensuring that milk products meet stringent safety and quality standards. The process begins with the separation of cream and milk, followed by precise standardization to achieve desired fat content levels.

Subsequently, the milk undergoes pasteurization, where it is heated to specific temperatures to eliminate harmful bacteria without compromising nutritional value . This combination guarantees a consistent, safe, and high-quality end product.

Tailored to Your Production Needs

At ProTrus, we understand that each dairy facility has unique requirements. Our systems are customizable to accommodate various capacities and product specifications. Whether you’re producing whole milk, skim milk, or cream, our equipment ensures optimal performance and adaptability.

Our lines are designed with energy efficiency in mind, incorporating advanced heat recovery systems and automation to reduce operational costs and environmental impact.

Contact Form

Comprehensive Support and Expertise

With years of experience in the dairy processing industry, ProTrus provides more than just equipment. We offer end-to-end support, from initial consultation and design to installation and after-sales service.

Our team of experts is dedicated to ensuring your production line operates at peak performance. Ready to enhance your dairy processing capabilities? Contact ProTrus today to discuss a solution tailored to your business.

Enhancing Dairy Processing Efficiency

ProTrus’s pasteurization and standardization line incorporates advanced technologies to optimize every stage of the process. Key components include:

- High-Precision Standardization Units: Ensure accurate fat content adjustments for consistent product quality.

- Efficient Pasteurization Systems: Utilize precise temperature controls to eliminate pathogens while preserving nutritional value.

- Automated Control Systems: Monitor and adjust processing parameters in real-time for optimal performance.

- Energy Recovery Mechanisms: Reduce energy consumption through innovative heat exchange technologies.

These components work in harmony to deliver a production line that is both efficient and adaptable to various product types.

Commitment to Quality and Compliance

At ProTrus, quality and compliance are paramount. Our equipment is manufactured following international standards, ensuring safety and reliability. We provide comprehensive documentation and support to assist with regulatory compliance and quality assurance processes.

Our production lines are designed for easy integration into existing facilities, minimizing downtime and facilitating a smooth transition to enhanced production capabilities.

Partner with ProTrus for Dairy Processing Excellence

Choosing ProTrus means partnering with a company committed to innovation, quality, and customer satisfaction. Our pasteurization and standardization lines are a testament to our dedication to providing solutions that meet the evolving needs of the dairy industry.

Experience the benefits of a production line designed for efficiency, flexibility, and superior product quality. Contact ProTrus today to learn how we can support your dairy processing goals.

Get in Touch Today

Get in touch today to explore how our dairy processing solutions can elevate your production efficiency and product quality.