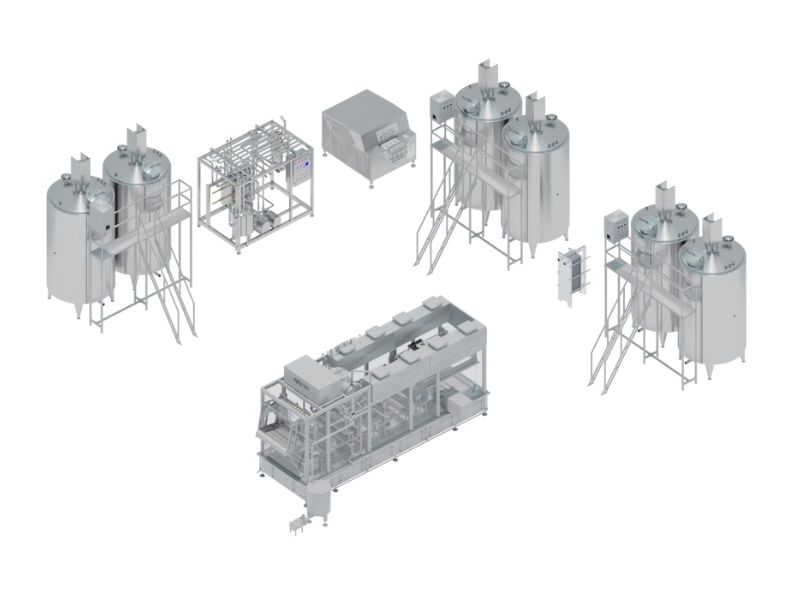

Ayran and Kefir Production Line

Enjoy flawless, continuous production of two of the world’s most popular cultured drinks with ProTrus’ integrated Ayran and Kefir Processing Line. From raw-milk reception to aseptic filling, every module is engineered for probiotic stability and consistent taste — all within a compact, Industry 4.0–ready footprint.

Integrated Fermentation & Pasteurization

Our line combines high-shear mixing, precise plate-heat pasteurization and double-jacket fermentation tanks that hold cultures at 38–42 °C for Ayran and 20–25 °C for Kefir, safeguarding both organoleptic quality and probiotic counts.

intermak.com.tr

Inline homogenizers running up to 2 × 2 500 psi disperse fat globules, giving Ayran its silky mouthfeel and preventing whey separation in bottled Kefir.

A closed-loop cooling circuit then drops product temperature below 6 °C in under five minutes, locking in flavor while reducing bacterial out-growth. Robust PLC control with SCADA interface lets operators store multiple recipes and push real-time data to MES platforms for OEE tracking.

Scalable Layouts from Artisan to Mega-Plant

Whether you’re adding a 3 000 L/day craft line or scaling to 30 000 L/h for retail giants, ProTrus offers modular valves, pumps and asynchronous filling carousels that expand without downtime.

Ready to grow? Contact us for a tailored line drawing and ROI projection within 48 hours.

Contact Form

Why Choose ProTrus Technology?

ProTrus designs, fabricates and FAT-tests every skid in the USA under ISO 9001 and 3-A Sanitary Standards. Our global service teams install, commission and train your staff on site, ensuring first-time-right start-ups and lifetime performance.

Fast Fermentation without Compromise

Dynamic agitators and spiral baffle tanks maintain uniform microflora, trimming fermentation times by up to 15 % while meeting the live-culture requirements that make Kefir a functional “super-drink.”

Energy-Efficient Pasteurization & Cooling

A regenerator section in the plate-heat exchanger recovers up to 94 % of thermal energy, cutting utilities and lowering your product’s carbon footprint.

Hygienic Design & CIP Integration

Five-step CIP cycles—pre-rinse, caustic, intermediate rinse, acid and final rinse—are executed automatically, slashing cleaning labor and water use by 40 %. Food-grade seals, sloped surfaces and orbital welds prevent microbial harborage, guaranteeing FSMA and EU EC 853/2004 compliance.

Smart Automation & Data Tracking

EtherNet/IP-ready sensors stream flow, Brix and pH to a central dashboard, enabling predictive maintenance and batch traceability demanded by major retailers and auditors.

Turnkey Support from ProTrus Experts

From feasibility to FAT, ProTrus engineers stay with you—delivering 3-D plant layouts, installation supervision and post-launch optimisation visits that keep yield high and downtime low.

Ready to future-proof your Ayran and Kefir line? Book a free process audit with ProTrus today and see how quickly you can scale fermented-dairy success.

Get in Touch Today

Get in touch today to explore how our dairy processing solutions can elevate your production efficiency and product quality.