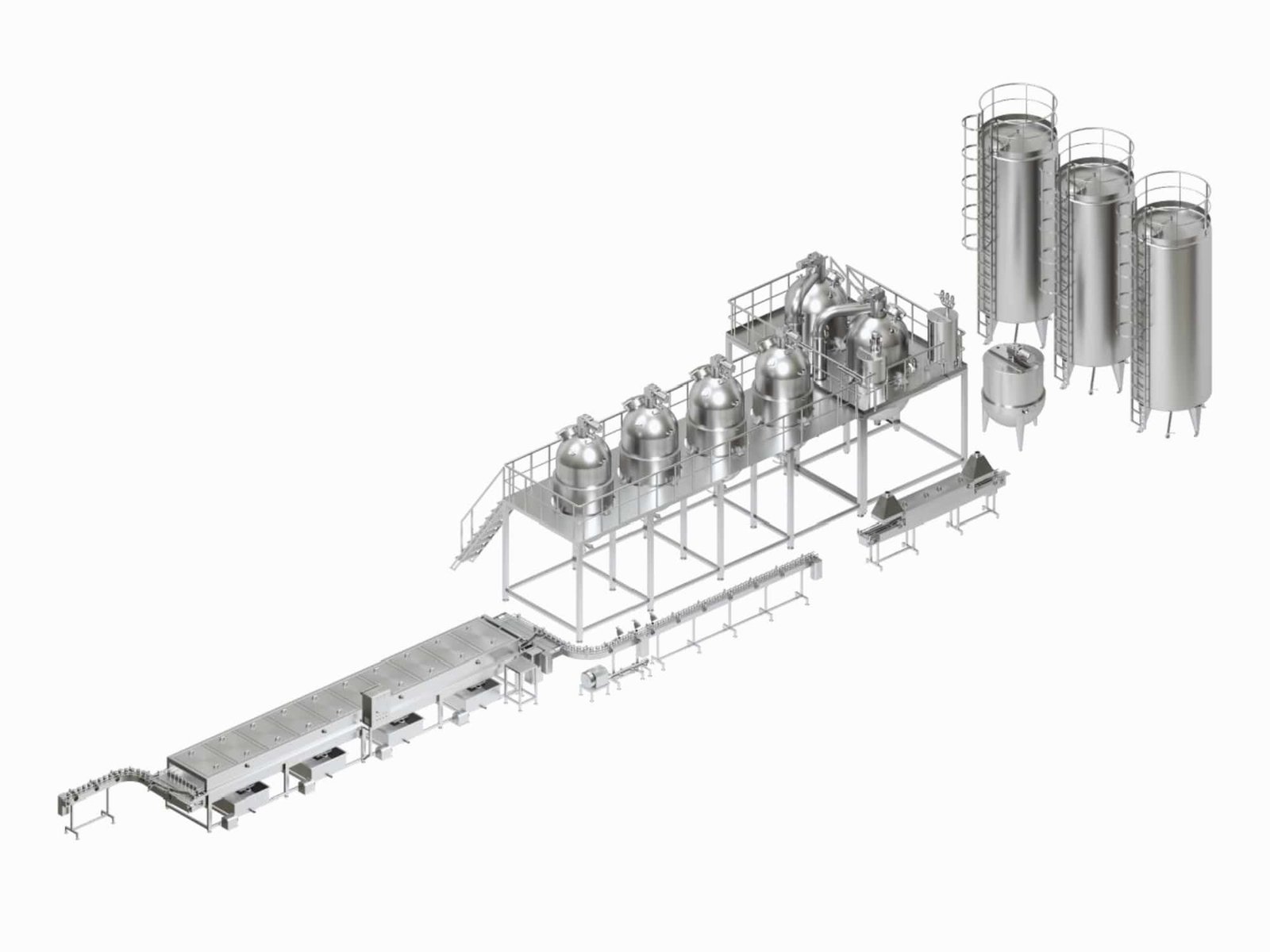

End-to-End Jam Processing Solutions

At ProTrus, we specialize in designing industrial jam production lines tailored for large-scale operations. Our systems cover the complete process flow: fruit preparation, cooking, concentration, filling, and capping—ensuring seamless production with minimal manual intervention.

Each line integrates cutting-edge components such as fruit washers, pulpers, vacuum kettles, inline mixers, deaerators, and servo-driven fillers. Whether processing berry, citrus, stone fruit, or tropical blends, ProTrus ensures accurate Brix control, color preservation, and natural flavor retention.

Turnkey Efficiency from Concept to Commissioning

ProTrus provides turnkey project delivery backed by decades of engineering and automation expertise. We support your production facility with:

- Custom 3D factory layout and process design

- CE-certified machinery under ISO 9001 standards

- Smart SCADA & PLC integration for full automation

Our team handles everything—from equipment manufacturing to installation, staff training, and after-sales service. With ProTrus, your jam line is production-ready on time and on budget.

Contact Form

Global Standards, Industrial Scalability

ProTrus equipment is designed for long-term reliability, ease of cleaning, and global food safety compliance. With successful installations in North America, Europe, and MENA, we serve clients seeking industrial scalability with localized technical support.

Comprehensive Jam Production Workflow

Our jam production lines offer a complete solution for consistent, high-volume output:

- Fruit Reception & Preparation: Sorting, washing, peeling, and cutting

- Cooking & Concentration: Batch or continuous vacuum kettles for rapid heating

- Mixing & Additive Integration: Inline dosing of sugar, pectin, acids, and flavors

- Deaeration & Homogenization: Smooth texture and extended shelf life

- Filling & Capping: Servo-driven systems for jars, bottles, or pouches

Optimized for Viscous, Particulate Products

Our systems are engineered to process jams with fruit chunks, seeds, or pulps without compromising flow or filling accuracy. Key features include:

- Agitator-equipped kettles to prevent sticking or burning

- Non-drip, cleanable nozzles

- Jacketed piping for thermal consistency

Automation & Real-Time Monitoring

Every line features intelligent automation for precision and traceability:

- SCADA-based recipe management

- Production batch reporting

- Temperature and pressure control systems

Versatile Packaging Options

Adapt your jam production line to match diverse market needs:

- Glass jars with twist-off lids

- Plastic containers

- Stand-up pouches with spouts

- Single-serve cups

Ready to scale your jam production with ProTrus?

Let our team design a high-efficiency jam production line that meets your industrial demands. Contact ProTrus today for a turnkey solution that enhances productivity, hygiene, and product quality.

Get in Touch Today

Get in touch today to explore how our dairy processing solutions can elevate your production efficiency and product quality.