Advanced CIP Systems for Critical Hygiene

ProTrus designs and manufactures fully automated CIP (Cleaning-in-Place) systems to meet the strict hygiene requirements of modern processing facilities. Whether in dairy, food, beverage, or pharmaceutical production, our CIP systems eliminate manual cleaning tasks, reduce contamination risks, and increase overall equipment availability.

Each CIP plant is customized based on your process needs—ranging from single-tank to multi-circuit solutions with acid, alkali, and rinse sequences. Our systems feature fully programmable PLC controls, heat exchangers for temperature control, flow and conductivity sensors, and hygienic pump assemblies—all CE-marked and built under ISO 9001 certification.

Turnkey Integration with Full Technical Support

ProTrus offers turnkey delivery of CIP systems, including:

* Custom piping layout and process design

* Equipment manufacturing and skid-mounted assembly

* Installation, operator training, and after-sales support

Our CIP solutions are seamlessly integrated into your existing SCADA or MES systems for complete cleaning traceability and remote monitoring.

Contact Form

Designed for Global Compliance & Efficiency

All ProTrus CIP plants comply with international hygiene regulations such as EHEDG and 3-A Sanitary Standards. We’ve deployed CIP systems worldwide—in the Americas, Europe, MENA, and Asia—backed by local service teams and remote diagnostics.

Why Choose ProTrus CIP Systems?

Key Benefits of CIP Technology

- Reduced Downtime: Clean without disassembling the equipment

- Consistent Results: Pre-programmed cycles ensure repeatable and validated cleaning

- Resource Efficiency: Lower water, energy, and chemical consumption

- Worker Safety: No manual tank entry or chemical handling

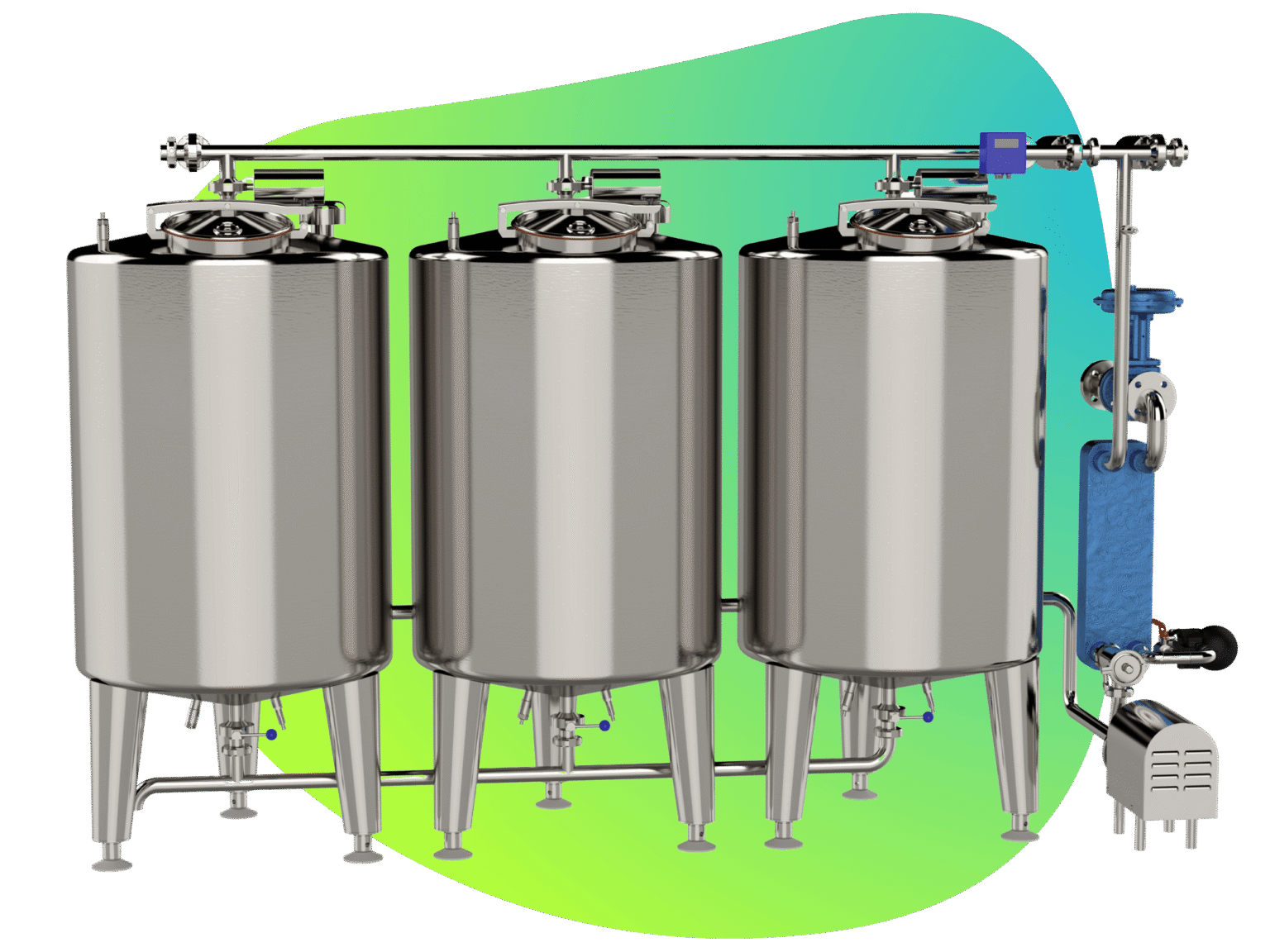

Components of a ProTrus CIP Plant

Each ProTrus CIP system may include:

- CIP tanks (alkali, acid, rinse, recovery)

- Heating units and heat exchangers

- Centrifugal and lobe pumps

- Flowmeters, conductivity, and temperature sensors

- Control panel with touchscreen HMI and PLC

- Automated valves and return flow management

Flexible Configurations for Every Industry

Our CIP systems are tailored for:

- Dairy Plants: Milk pasteurizers, yogurt tanks, UF lines

- Beverage Processing: Mixing tanks, syrup lines, carbonation units

- Sauce and Viscous Food Lines: Ketchup, mayonnaise, jams

- Pharmaceutical and Biotech: Sterile tanks, reactors, cleanrooms

We offer both centralized and decentralized CIP configurations, along with mobile units for small-scale operations or pilot plants.

Smart Automation and Documentation

ProTrus CIP systems integrate with existing factory automation systems for:

- Real-time monitoring and alarm logs

- Digital cleaning records and batch validation

- Remote access and troubleshooting

Looking to upgrade your plant hygiene and efficiency?

Contact ProTrus today to discuss your CIP system needs. Let us engineer a turnkey, high-performance cleaning solution tailored to your process line—ensuring hygiene, compliance, and operational excellence.

Get in Touch Today

Get in touch today to explore how our dairy processing solutions can elevate your production efficiency and product quality.