Engineered for High-Quality Detergent Manufacturing

ProTrus offers a fully automated production line for liquid dishwashing detergents, designed to handle a wide range of formulations including concentrated, antibacterial, and eco-friendly variants. This line ensures optimal viscosity, pH stability, and surfactant dispersion—key for effective cleaning performance and product shelf life.

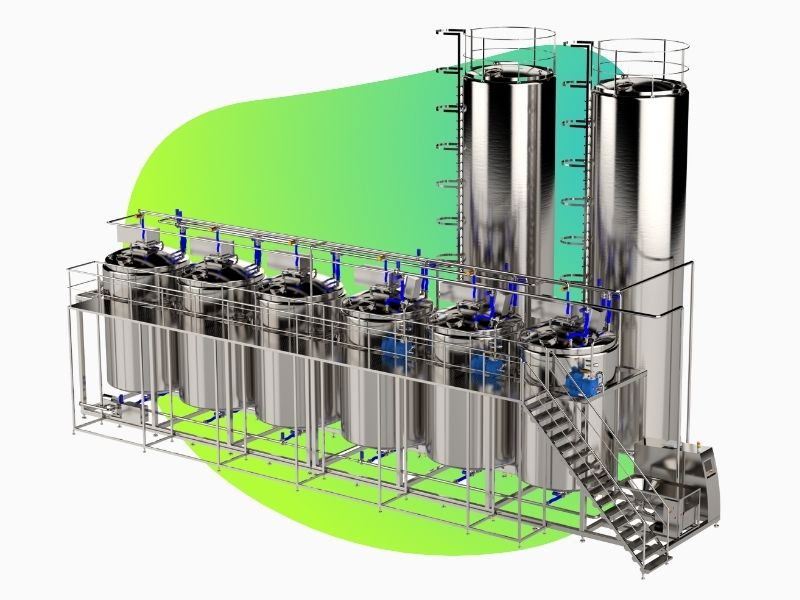

Each system includes mixing vessels with agitation control, high-shear homogenizers, dosing units, and temperature-regulated tanks, all configured for accurate ingredient blending and minimal residue retention.

Complete Turnkey Delivery with Smart Automation

From design to commissioning, ProTrus delivers your dishwashing detergent line as a turnkey solution. Systems are fully automated with PLC/SCADA platforms for real-time monitoring, batch tracking, and recipe management.

The production line can be tailored for small, medium, or large-scale output with integration of inline quality control, CIP (Clean-in-Place) stations, and filling-packaging systems. Our engineers ensure compliance with GMP and ISO 9001 standards, delivering operational safety and regulatory reliability.

Need to scale your detergent production? Contact ProTrus for a custom-configured line.

Contact Form

Hygienic, Durable, and Operator-Friendly Design

Made with stainless steel (AISI 316/304), all equipment is built for long-term performance in aggressive chemical environments. Easy-access platforms, safety interlocks, and intuitive controls ensure safe and ergonomic operation.

What Makes Liquid Dishwashing Detergent Production Unique?

Dishwashing detergents require precise balancing of surfactants, fragrances, thickeners, and preservatives. Maintaining viscosity and avoiding phase separation are critical to producing a high-performing, market-ready product.

Core Equipment in a ProTrus Detergent Production Line

Our standard line includes:

- Batch and continuous mixing tanks

- High-speed agitators and dispersers

- Inline homogenizers for ingredient blending

- pH and viscosity sensors for quality control

- Automatic dosing and weighing units

- CIP-ready tanks and piping systems

Benefits of Full Automation in Detergent Lines

- Enhanced production efficiency and repeatability

- Reduced downtime and manual error

- Real-time monitoring with SCADA integration

- Safer chemical handling and operator control

- Faster cleaning and changeovers

Global Experience, Local Execution

With over 15 years of expertise and installations across five continents, ProTrus delivers detergent manufacturing systems trusted by global FMCG and private-label producers. All equipment is CE-marked and supported with remote service and spare parts logistics.

Let ProTrus elevate your cleaning product production.

Request your quote today for a scalable liquid dishwashing detergent line tailored to your needs.

Get in Touch Today

Get in touch today to explore how our dairy processing solutions can elevate your production efficiency and product quality.