Plant Root Dye Production Line

Harness the power of nature with ProTrus’s plant root dye production line—engineered for efficient, scalable, and eco-friendly extraction of botanical pigments.

Eco-Friendly Solutions for Botanical Dye Manufacturing

ProTrus offers a fully integrated plant root dye production line designed for the extraction and processing of natural colorants from roots such as madder, turmeric, beet, and alkanet. These pigments are widely used in textiles, cosmetics, pharmaceuticals, and food coloring applications.

The system supports both water-based and solvent-based extractions, with precise temperature, pressure, and agitation control to protect the integrity and vibrancy of natural pigments. All equipment is designed to maximize yield, reduce oxidation, and minimize thermal degradation during processing.

Turnkey System with Automated Control

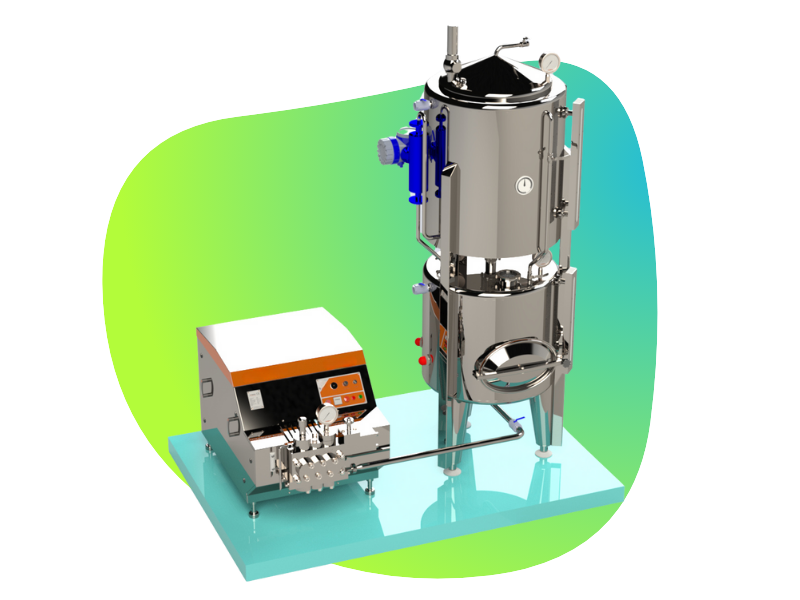

Each plant root dye production line is delivered as a turnkey project—complete with extraction vessels, filtration units, decanters, concentration tanks, and drying modules (e.g., spray dryers or vacuum evaporators). The system is operated via a centralized PLC/SCADA interface for real-time monitoring and full traceability.

ProTrus also provides 3D layout planning, installation, validation, and after-sales support, ensuring a fully GMP-compliant setup for natural dye production.

Looking to scale sustainable dye manufacturing? Contact ProTrus to design your custom production line.

Contact Form

Hygienic and Modular Construction

Built from food- and pharma-grade stainless steel, the system ensures safe contact with organic materials. Modular design enables easy cleaning, expansion, and product changeovers, while Clean-in-Place (CIP) functions reduce downtime.

What Is a Plant Root Dye Production Line?

A plant root dye production line extracts natural pigments from botanical roots through mechanical, thermal, and chemical processes. These dyes are valued for their biodegradability, non-toxicity, and aesthetic richness, especially in sustainable textile and personal care markets.

Key Components of the ProTrus System

A complete root dye extraction line includes:

- Crushing and milling units for root preparation

- Solvent or aqueous extraction vessels

- Filtration and clarification modules

- Concentration tanks and vacuum evaporators

- Spray dryers or freeze dryers for powder conversion

- SCADA-based automation and batch logging

Benefits of Automating Natural Dye Production

- Enhanced color stability and extraction efficiency

- Reduced solvent use through closed-loop recovery

- Accurate process control with less operator intervention

- Adaptable to various root-based raw materials

Global Turnkey Experience with ProTrus

With 15+ years of process engineering excellence, ProTrus has delivered customized natural extraction lines to producers in Europe, the Americas, and Asia. Our CE-certified systems are known for energy efficiency, safety, and sustainable design.

Bring nature to industry with ProTrus’s plant root dye technology.

Request your quote now to start producing high-quality natural dyes at scale.

Get in Touch Today

Get in touch today to explore how our dairy processing solutions can elevate your production efficiency and product quality.