Stainless Steel

Bioreactors | Fermenters

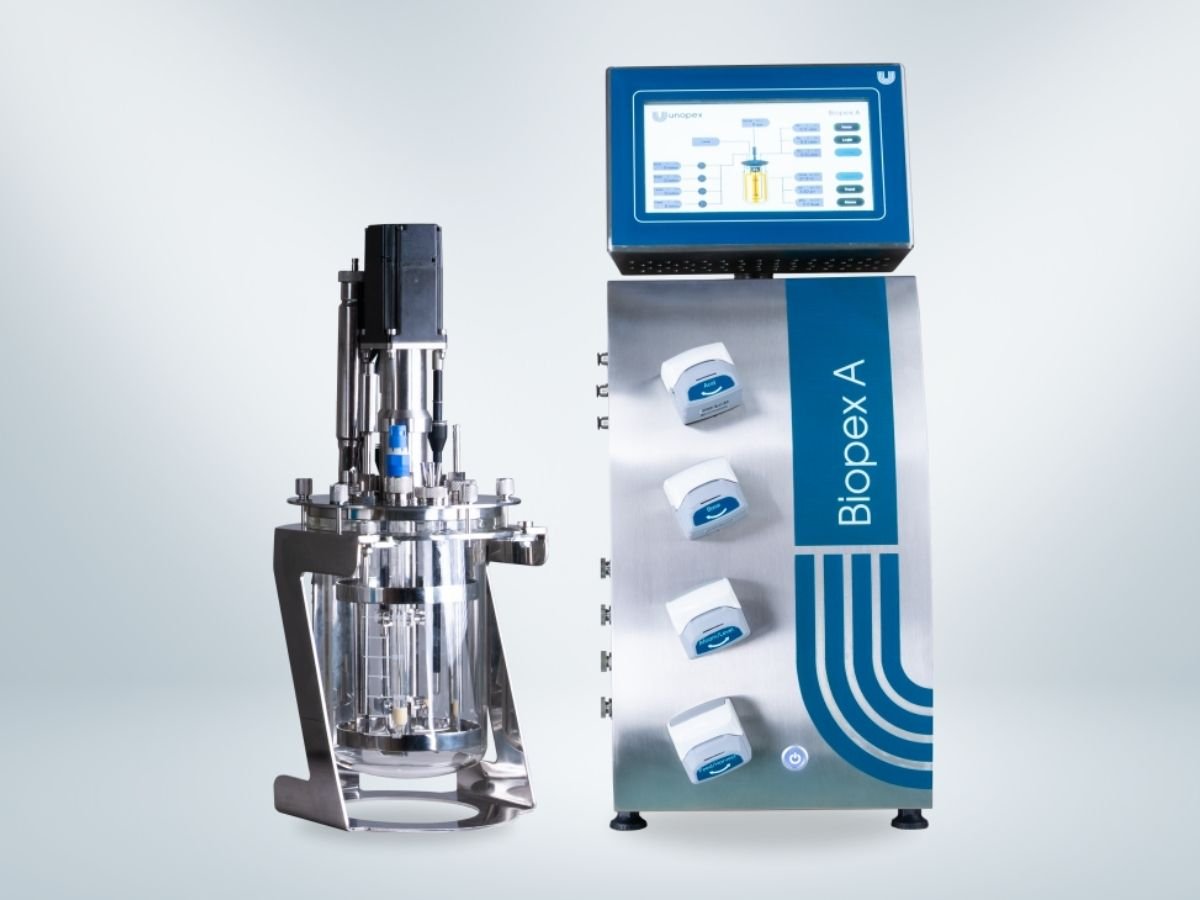

Discover Unopex stainless steel bioreactors—engineered for pharmaceutical, biotech, and industrial fermentation with CIP/SIP, SCADA integration, and full compliance.

Scale Up

Benchtop bioreactors are useful for initial trials. The results from a successful test conducted on the Biopex A benchtop bioreactor can be utilized in the scale-up procedure to pilot and industrial production.

Built for Reliability, Engineered for Scale

Unopex Stainless Steel Bioreactors are purpose-built for advanced microbial and cell culture fermentation in production environments. Designed to meet GMP, CE, and 21 CFR Part 11 standards, these systems ensure sterile operation with CIP (Clean-in-Place) and SIP (Sterilization-in-Place) as standard.

With vessel volumes ranging from 30 L to over 10,000 L, our bioreactors support upstream processing in pharmaceuticals, biotech, enzyme production, and vaccine manufacturing.

Intelligent Automation and Process Control

Equipped with a centralized control system, these fermenters offer:

- PLC + SCADA or DCS integration

- Precise PID loop control for pH, DO, foam, level, temperature, stirrer

- Fully welded or modular vessel design

- Mass flow controllers and gas mixing stations

🔧 Request a quote for a customized stainless steel bioreactor configuration that suits your scale and process.

Contact Form

Key Technical Specifications

- Volume Range: 30 L – 10,000 L (customizable)

- Material: AISI 316L with electro-polished surface finish

- Temperature Control: Double-jacketed with thermal fluid or steam

- Agitation: Top or bottom mounted with mechanical seal

- Sensors: pH, DO, temperature, pressure, foam/level

- Cleaning: Fully automated CIP/SIP system

- Control System: Siemens/Allen Bradley PLC with SCADA interface

- Compliance: CE, cGMP, 21 CFR Part 11, ASME BPE

- Connections: Tri-clamp, aseptic valves, sterile sampling ports

Engineered for Biopharmaceutical Demands

From seed fermentation to full-scale production, Unopex stainless steel bioreactors offer a contamination-free environment with high mixing efficiency and flexible gas management, supporting both aerobic and anaerobic processes.

Custom Configurations for Every Process

Whether you need batch, fed-batch, or perfusion operation modes, our systems can be tailored with optional accessories like antifoam dosing, gravimetric feeding, and automated harvesting for continuous performance.

Total Visibility and Compliance

Integrated SCADA enables real-time trend analysis, remote access, and complete batch documentation. Secure user-level access and audit trails support data integrity and regulatory inspections.

Industries We Serve

Our stainless steel bioreactors are trusted by clients in pharma, industrial biotechnology, nutraceuticals, food enzymes, and academic pilot plants. With global references and ISO 9001-certified manufacturing, Unopex delivers systems built for long-term reliability.

Get in Touch Today

Get in touch today to explore how our dairy processing solutions can elevate your production efficiency and product quality.