Cosmetic Processing Solutions

ProTrus delivers turnkey cosmetic processing solutions that ensure exceptional product consistency, hygienic design, and fully automated operation—tailored to meet the evolving needs of the global personal care industry.

Our Cosmetic Processing Solutions

Engineered for High-Performance Cosmetics

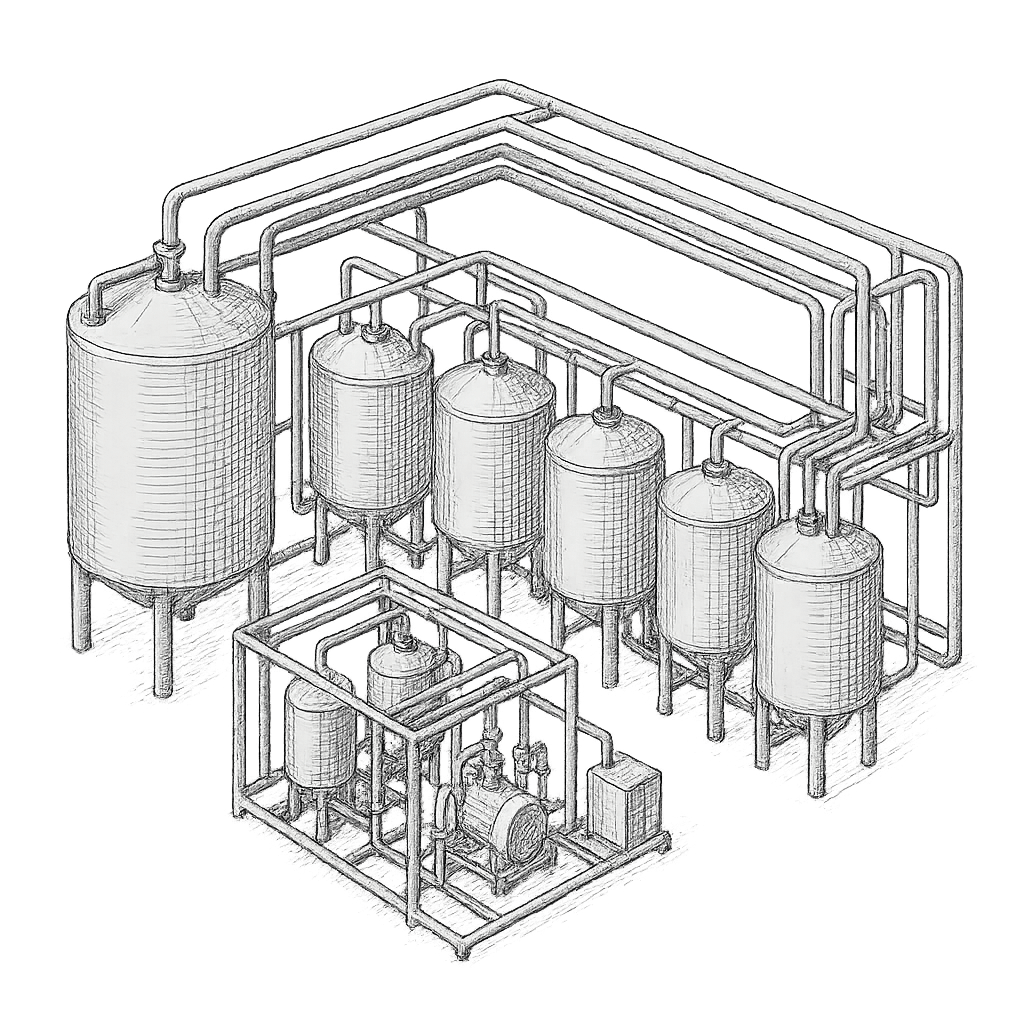

ProTrus designs and manufactures complete process lines for the cosmetic industry, including production of creams, lotions, gels, emulsions, shampoos, conditioners, and liquid soaps. All systems are developed with precision-controlled mixing, homogenization, emulsification, and heating/cooling capabilities to ensure repeatable product quality.

From pilot-scale development units to large-scale manufacturing systems, ProTrus equipment supports rapid product changeover, CIP (Clean-in-Place) functionality, and SCADA-ready automation. These turnkey solutions are ideal for manufacturers seeking hygienic, energy-efficient, and regulation-compliant production facilities.

Contact Form

Turnkey Project Delivery

ProTrus cosmetic processing lines are built for GMP compliance and efficient operation. Each solution integrates high-shear inline mixers, homogenizers, and stainless-steel process tanks with agitation, heating/cooling jackets, and full automation capability. Our systems are designed to reduce human error, increase yield, and ensure perfect emulsification for consistent texture and stability.

From emulsified sunscreens to thick body butters, ProTrus ensures optimal product quality while minimizing downtime and energy use.

Looking for a tailor-made line? Contact ProTrus today to start your project.

Cosmetic Process Engineering for the Future

Cosmetic manufacturers across the Americas are under increasing pressure to comply with strict safety standards, reduce production costs, and accelerate time-to-market. ProTrus meets these challenges by delivering modular, fully integrated systems that streamline production and maintain the highest hygienic standards.

High Emulsion Stability

ProTrus homogenization systems produce ultra-fine emulsions critical to lotions and creams, ensuring no phase separation and silky-smooth textures.

Flexible Batch Production

Our tanks and mixing vessels are designed for both small and large batch production, making it easy to scale operations or test new formulations without reconfiguring your entire line.

Eco-Conscious Design

ProTrus lines are engineered for low energy consumption and minimal product waste. Features like heat recovery and CIP save resources while supporting sustainability goals.

Full Lifecycle Support

From layout and engineering to installation, validation, and after-sales service, ProTrus provides end-to-end expertise—ensuring long-term performance and ROI.

Get in Touch Today

Get in touch today to explore how our dairy processing solutions can elevate your production efficiency and product quality.