Automatic Wafer Production Line

ProTrus offers a state-of-the-art Automatic Wafer Production Line designed to produce high-quality flat or hollow wafer products at industrial scale. From dough depositing to final product cutting, every component of the line is built for durability, hygiene, and continuous high-speed performance.

Our Automatic Wafer Production Line

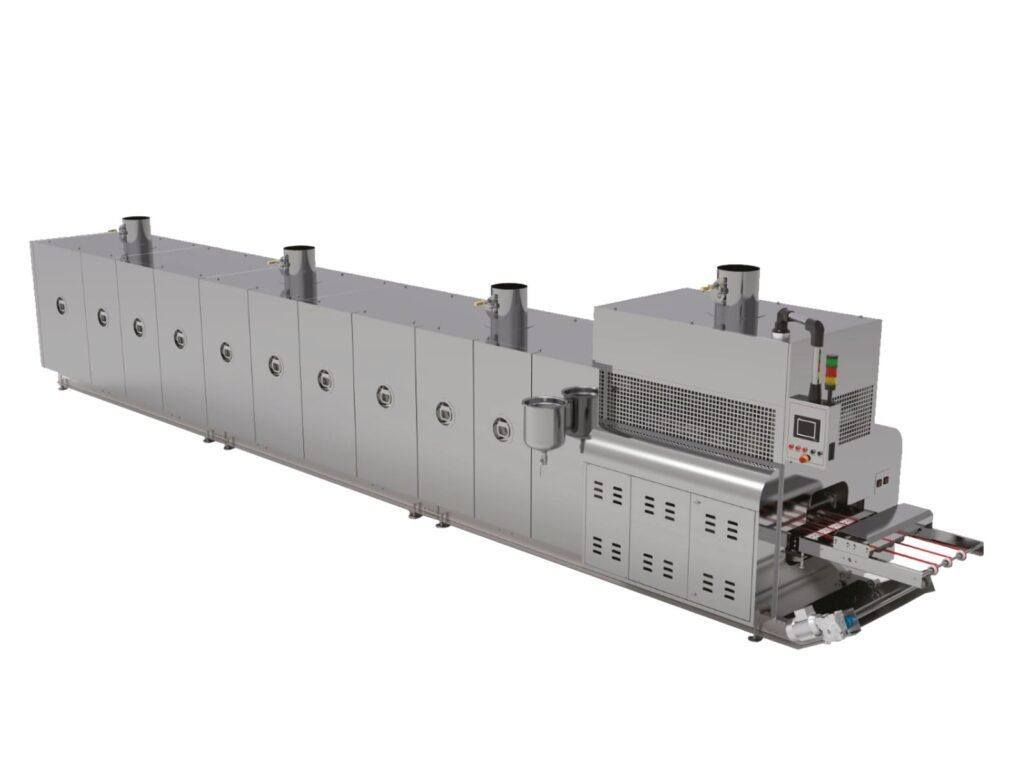

Precision Wafer Baking Oven

At the heart of the line is the Automatic Wafer Baking Oven, engineered for even baking and energy savings. It features chrome-coated cast plates for uniform heat distribution and a frequency-controlled reduction drive for consistent operation. In case of power loss, manual turning is available for operational safety. The oven also includes:

- Insulated structure for heat efficiency

- Dough drip prevention via crawler pump

- Easy-access lids for maintenance

- Automatic sheet take-off system

Contact Form

Stress-Free Wafer Cooling System

Once baked, wafers are cooled with the Wafer Sheet Cooling System, which allows up to 90 wafer sheets to be cooled evenly at ambient temperature. With a modular aluminum frame and 2-meter passage height, operators can move freely through the line without disruption.

- Stainless steel inner sheeting for hygiene

- 2–3 minute cooling time for optimal conditioning

- Archway design for ergonomic line layout

Cream Spreading with Precision Control

The Wafer Cream Spreading Machine enables the even application of liquid or solid creams using contact or thin-film methods. Available in single or two-color versions, it includes optional upgrades such as:

- Hazelnut droppers

- Weight measurement systems

- Full PLC control for accuracy and repeatability

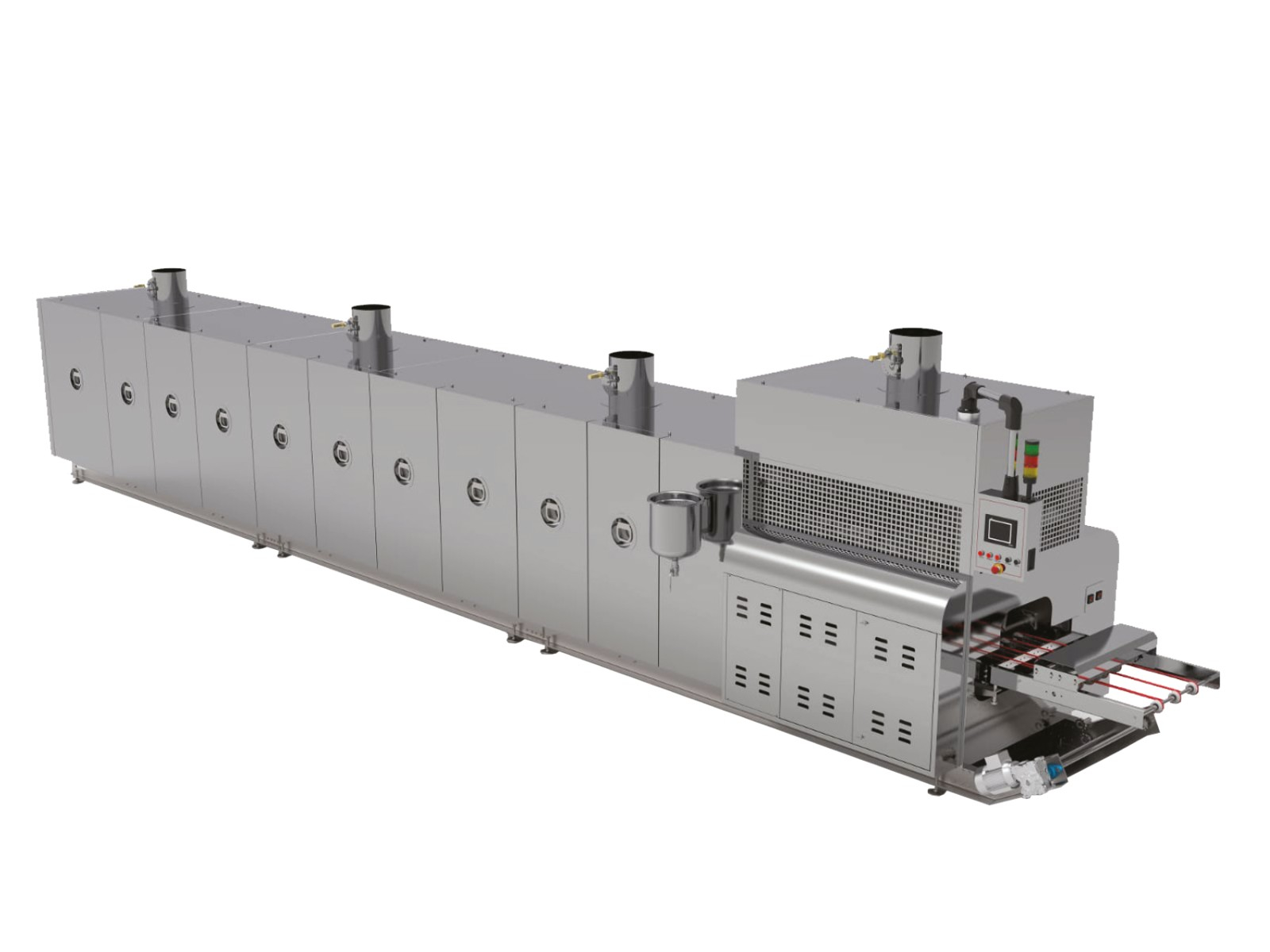

Tunnel-Type Wafer Book Cooler

Post-spreading, the cream-filled wafers are transported through the Wafer Book Cooler, which accommodates up to 90 plates and maintains product quality with a tunnel cooling capacity of 20,000 kcal/h. The system includes:

- Stainless steel cooling tunnel

- Entrance/exit sealing with O-ring tapes

- Automated unloading and product alignment system

- Cooling gas: A404

High-Speed Wafer Cutting & Distribution

Finally, wafers are trimmed and sized using the Wafer Cutting and Distribution System. This module ensures minimal waste (max. 5%) and clean cuts through robust stainless steel knives on modular frames.

- Single or double-cutter options

- Automatic infeed system

- Longitudinal block turner for flexible feeding

- Capacity up to 14 blocks/minute

Engineered for Performance, Designed for Growth

The ProTrus Automatic Wafer Production Line is modular, scalable, and optimized for hygienic food processing. Each stage of the line is built to operate in synchronization, reducing labor and increasing overall efficiency.

Why Choose ProTrus Wafer Lines?

- Industrial-grade performance with low maintenance

- High-efficiency energy usage and minimal product loss

- Full automation with user-friendly control panels

Get in Touch Today

Get in touch today to explore how our dairy processing solutions can elevate your production efficiency and product quality.