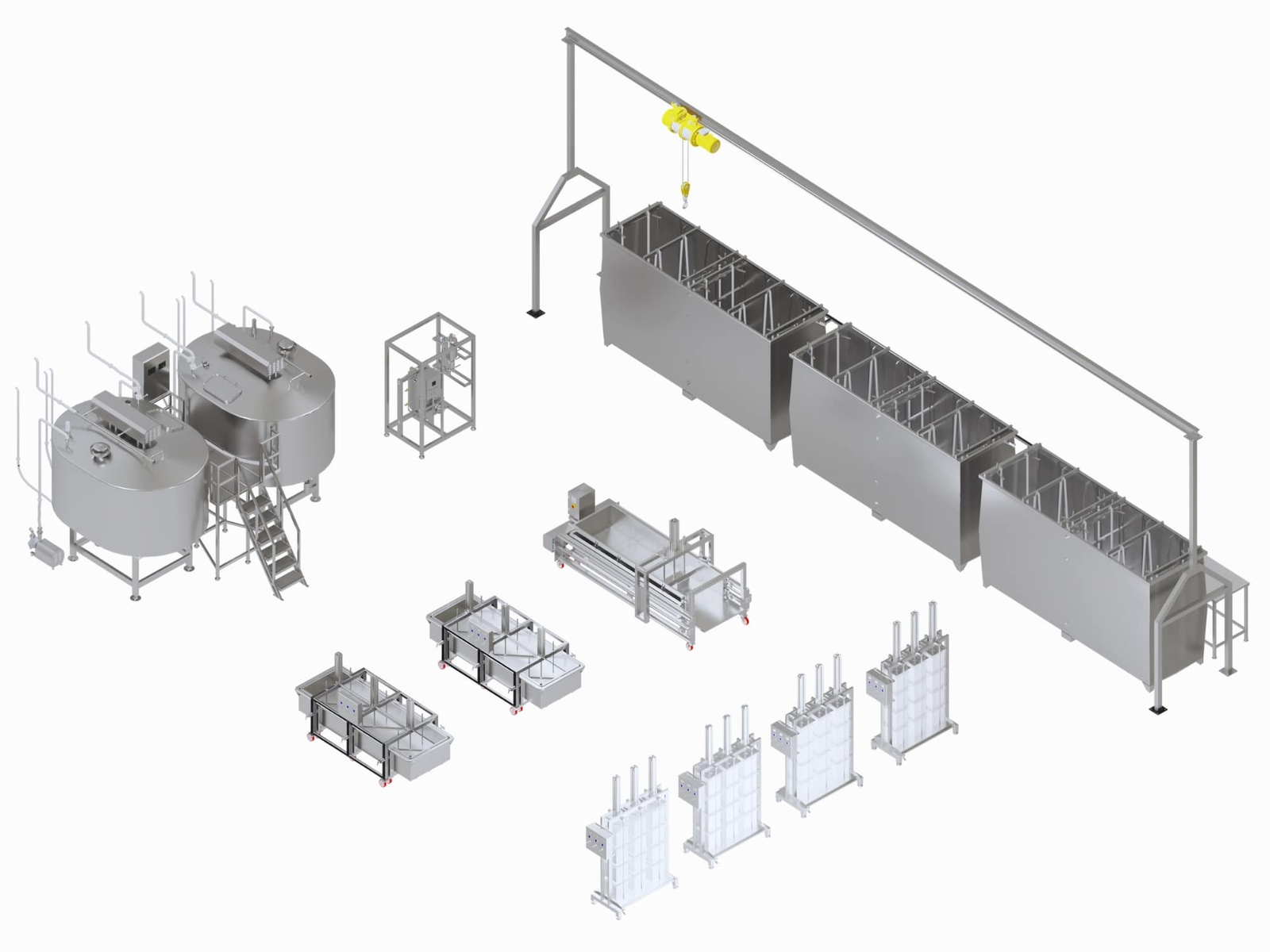

Hard and Semi-Hard Cheese Production Line

Our hard and semi-hard cheese production line is designed for precision, hygiene, and consistency—supporting dairy manufacturers in producing varieties like Gouda, Cheddar, and Kashkaval at industrial scale.

From Milk Intake to Maturation: Fully Controlled Cheese Production

The line begins with milk standardization and pasteurization, followed by enzyme and culture dosing through fully automated modules. Coagulation takes place in horizontal cheese vats with automated cutting knives to ensure uniform curd structure.

After whey drainage, curds are pre-pressed and transferred into block molds or horizontal pressing units. Whey recovery, salt addition, and optional cheddaring conveyors (for cheddar-type cheeses) are integrated. Post-pressing stages include brining tanks, maturation rooms, and customizable packaging units, such as vacuum or MAP systems.

Each phase is designed for maximum food safety, minimal manual handling, and optimal yield control.

Adaptable Systems for Global Cheese Standards

Whether producing for domestic markets or export, our production lines comply with all major international food safety and performance standards: CE, ISO 9001, FDA, and USDA (on request).

Our engineering team designs plant layouts based on your product type, volume, and facility footprint.

Let’s build your cheese success—contact us for a custom plan.

Contact Form

Scalable Capacity, Future-Proof Investment

Our systems offer flexible capacities from 1,000 L/h to over 20,000 L/h, with upgrade options to integrate pasteurizers, CIP stations, whey processing systems, and full SCADA control.

Industrial Cheese Production Line Tailored for Hard and Semi-Hard Varieties

Hard and semi-hard cheeses require longer processing and aging periods, making consistency and yield efficiency critical. Our cheese production line supports the entire cycle—milk preparation, curd handling, pressing, and ripening—within a closed, hygienic, and automated system.

Which Cheeses Can Be Produced with This Line?

This line is suitable for:

- Cheddar

- Gouda

- Emmental

- Edam

- Kashkaval

- Manchego

- Tilsit

Why Invest in a Hard and Semi-Hard Cheese Line?

These cheeses command higher market value but require specialized handling. Automation reduces labor costs, stabilizes quality, and extends shelf life. Our systems ensure:

- Controlled moisture and pH levels

- Uniform brining and maturation

- High cutting and pressing accuracy

Integration, Automation & Data Monitoring

The line is SCADA and PLC compatible, allowing real-time data collection, batch traceability, and recipe management. Seamless integration with your ERP or MES ensures full production visibility.

Global Turnkey Services

We offer turnkey delivery:

- Feasibility study and factory layout

- 3D simulation and engineering

- Manufacturing and site installation

- Operator training and lifecycle support

Get in Touch Today

Get in touch today to explore how our dairy processing solutions can elevate your production efficiency and product quality.