Scalable Solutions for Cosmetic-Grade Hair Care

ProTrus offers a turnkey shampoo and conditioner production line designed to meet the rigorous demands of the personal care industry. From sulfate-free shampoos to rich, creamy conditioners, our line ensures perfect ingredient blending, viscosity control, and product stability.

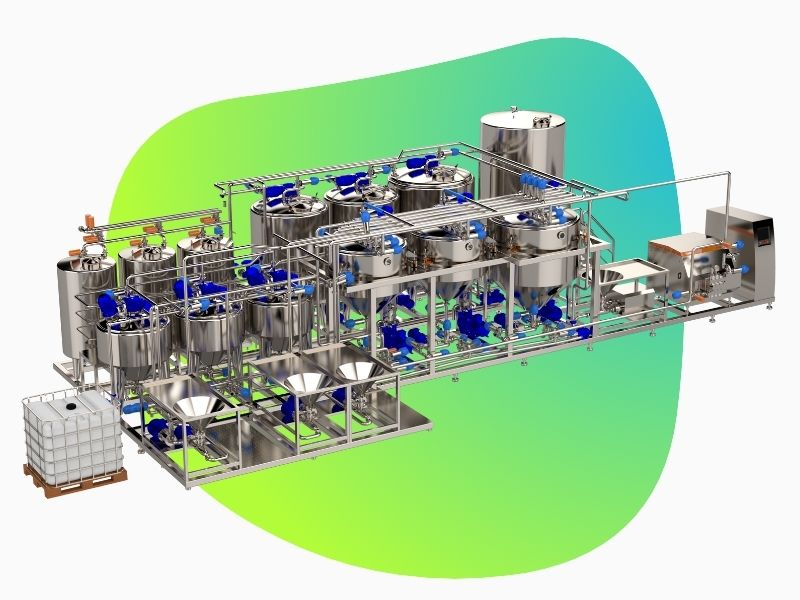

The system includes high-shear mixers, jacketed tanks with precise temperature control, inline homogenizers, and vacuum de-aeration units—all optimized for surfactants, emollients, silicones, and botanical additives. Whether your production is batch-based or continuous, ProTrus ensures repeatability and regulatory compliance at scale.

Fully Integrated Turnkey Delivery

Our shampoo and conditioner production line is delivered as a complete, ready-to-run solution. We provide 3D layout design, mechanical/electrical installation, and comprehensive training. All equipment is integrated with SCADA/PLC automation for real-time monitoring, recipe management, and quality control.

The system supports quick product changeovers with Clean-in-Place (CIP) capability, helping reduce downtime and cross-contamination risk. ProTrus solutions are GMP-compliant and suitable for both premium brands and private-label production.

Looking to enhance your personal care product output? Get in touch with ProTrus for a custom-configured line today.

Contact Form

Hygienic Design & Long-Term Performance

All product-contact parts are AISI 316 stainless steel, with mirror-polished surfaces to minimize contamination and ease cleaning. The system is built for high durability, even in formulations with thickening agents or active ingredients.

What Are the Challenges in Shampoo and Conditioner Production?

Producing hair care products involves complex emulsification, pH balancing, and thickening processes. Each formulation demands precise ingredient dosing, controlled shear levels, and stable viscosity to ensure consistent texture, shelf-life, and user experience.

What Does the Production Line Include?

A typical ProTrus hair care line includes:

- Batch and inline mixers with jacketed heating/cooling

- High-shear homogenizers for smooth emulsions

- Vacuum systems for de-aeration

- Viscosity and pH sensors for QC

- CIP-ready piping and tanks

- Filling and capping units for final packaging

Key Benefits of a ProTrus Hair Care Line

- Fast batch processing with consistent quality

- Reduced downtime through automation and CIP

- Real-time control of temperature, pH, and viscosity

- Regulatory compliance with GMP and ISO 9001

- Energy-efficient, scalable equipment

Proven Experience in Cosmetic Manufacturing

With over 15 years of experience, ProTrus has installed cosmetic production lines across the Americas, Europe, MENA, and Asia. Our CE-certified equipment and end-to-end service ensure your production meets global standards with local support.

Advance your cosmetic production with ProTrus technology.

Request a consultation today to build your turnkey shampoo and conditioner line with confidence and precision.

Get in Touch Today

Get in touch today to explore how our dairy processing solutions can elevate your production efficiency and product quality.