White Cheese Production Line – Turnkey Manufacturing

Our white cheese production line is engineered to deliver consistent quality, high capacity, and full automation—meeting the growing global demand for traditional white cheeses like Feta and Beyaz Peynir.

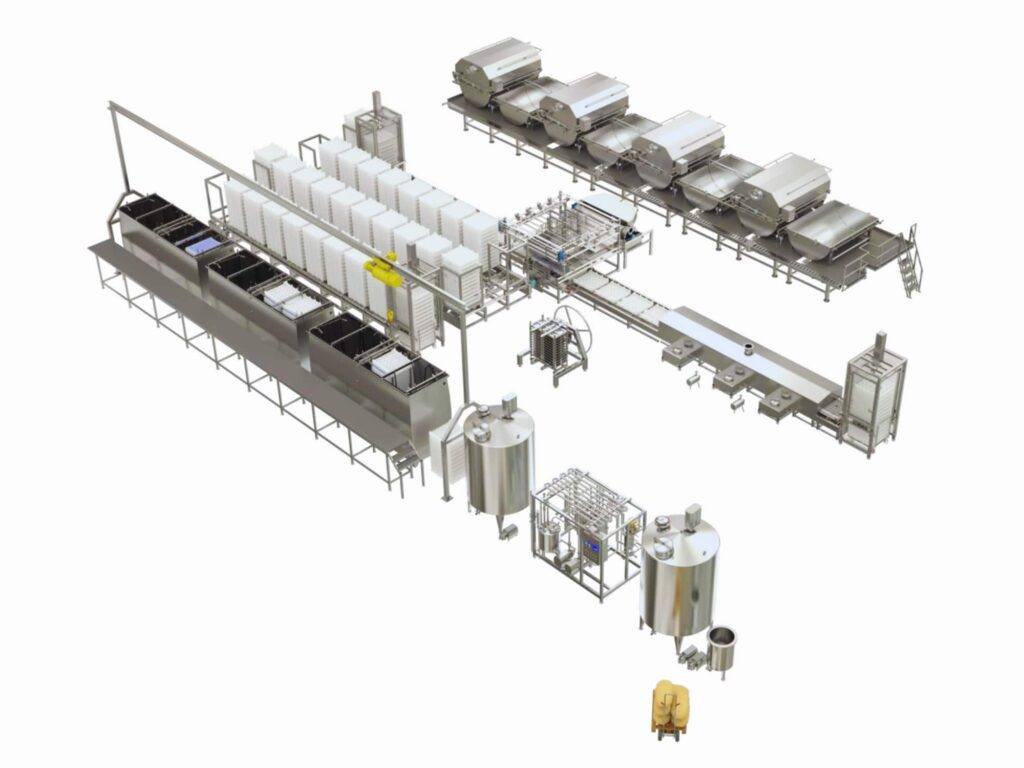

Optimized Workflow from Milk Reception to Cheese Packaging

Our line begins with precise milk standardization and pasteurization, ensuring optimal curd formation. The coagulation, cutting, and whey drainage stages are carefully automated for uniform results. Optional ultrafiltration and pre-pressing modules can be integrated for moisture control. Final steps include block molding, brining, maturation, and vacuum or thermoform packaging—tailored to customer requirements.

Each stage is designed with energy efficiency and hygiene in mind, using stainless steel components and PLC-based control systems for reliable operation.

Tailored Solutions, Global Compliance

Whether producing traditional white cheese for local markets or export-grade product for international distribution, our systems comply with global standards including CE, ISO, and USDA.

Our team works with you from design to installation to develop a fully tailored system aligned with your production goals.

Get in touch today to request a detailed layout and customized offer.

Contact Form

Modular Design for Scalable Growth

With modular units ranging from 500 to 10,000 L/h capacity, this line allows for gradual investment and expansion. Whether you’re upgrading from semi-manual operations or launching a new facility, our design ensures long-term performance with minimal downtime.

Technical Insight and Industry Applications

Why White Cheese Production Requires Specialized Systems

White cheese is delicate and highly sensitive to processing conditions. Variations in temperature, pH, and brine concentration can affect texture and taste. That’s why our systems offer real-time monitoring and recipe control, guaranteeing consistent results.

Integration with Existing Dairy Infrastructure

We offer integration with existing milk processing lines, fermentation tanks, or packaging units. Our engineering team can also retrofit legacy systems for compatibility with new automation modules.

Hygiene & Cleaning Systems (CIP Ready)

Each module supports clean-in-place (CIP) procedures with validated sanitization cycles. This ensures food safety and reduces water and chemical consumption.

After-Sales Support & Remote Monitoring

All lines are delivered with training, documentation, and remote monitoring capabilities. We also offer preventive maintenance contracts and spare parts worldwide.

Ready to modernize your white cheese production? Contact us today to explore a tailored solution that enhances product quality, reduces manual labor, and meets international standards.

Get in Touch Today

Get in touch today to explore how our dairy processing solutions can elevate your production efficiency and product quality.