Chemical & Cosmetics Processing Solutions

ProTrus delivers advanced processing solutions for the chemical and cosmetics industries, combining hygienic stainless-steel design with high automation, precision mixing, and thermal control. Our turnkey systems are ideal for producing creams, lotions, gels, emulsions, and industrial chemical products.

Our Chemical Processing Solutions

Engineered Systems for Chemical Manufacturing

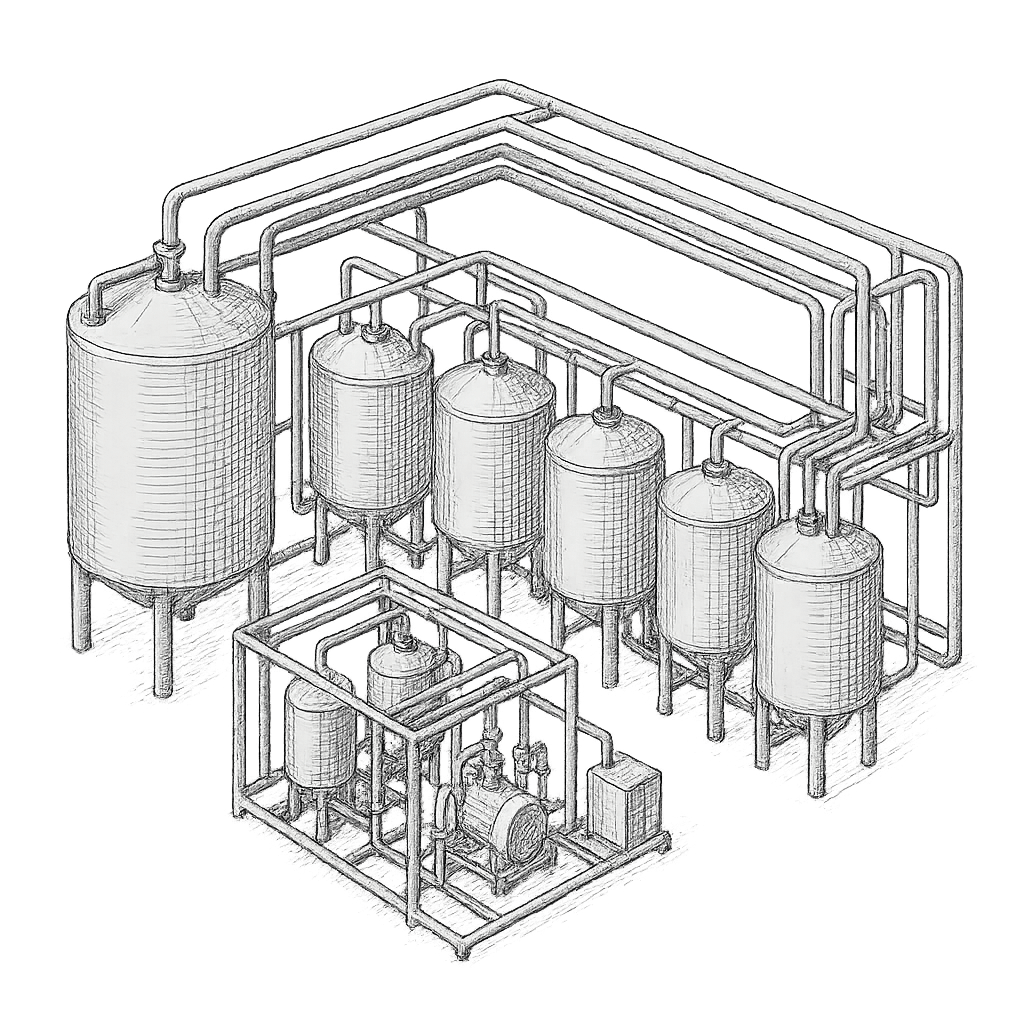

At ProTrus, we specialize in the design and delivery of process systems for liquid chemical production, transfer, and formulation. Our equipment is ideal for applications such as detergents, cleaning agents, emulsions, solvents, lubricants, and industrial fluids.

Each system is engineered for chemical compatibility, corrosion resistance, and precision control. From jacketed reactors and mixing vessels to dosing skids and clean-in-place (CIP) units, ProTrus ensures seamless integration with your production environment and safety protocols.

Contact Form

Turnkey Project Delivery

We provide full-cycle engineering services for your chemical process line, including:

We provide full-cycle engineering services for your chemical process line, including:

- Feasibility and process flow design

- 3D layout planning and technical drawings

- Equipment manufacturing, testing, and validation

- On-site installation, commissioning, and staff training

Our solutions are delivered fully assembled and factory-tested—ready for operation upon delivery.

Built to Global Standards

All ProTrus systems are designed to meet international industry regulations, including ATEX compliance where required. Our manufacturing process follows ISO 9001 quality standards, and every component is selected based on chemical resistance, operational safety, and performance.

Advanced SEO Section: Benefits & Features of ProTrus Chemical Systems

Core Applications

Our chemical processing lines serve a wide range of industries:

- Household & Industrial Cleaning: Surface cleaners, degreasers, disinfectants

- Water Treatment: pH control agents, coagulants, flocculants

- Lubricants & Additives: Oils, greases, antifreeze

- Agricultural Chemicals: Liquid fertilizers, crop protection agents

Smart Dosing & Recipe Control

ProTrus systems include advanced automation features such as:

- PLC-controlled dosing and mixing sequences

- Flow, pressure, and pH sensors for real-time feedback

- Batch tracking and recipe management

- SCADA integration for central control and monitoring

Hygienic and Safe Processing

Our systems include:

- Sealed tanks with exhaust and pressure control

- ATEX-rated motors and components for volatile chemicals

- Fully automated CIP for internal cleaning

- Double-jacketed vessels for thermal regulation

Flexible, Scalable Designs

Whether you’re running a pilot facility or a large-scale operation, ProTrus offers flexible tank volumes, modular skids, and scalable architecture. Our systems adapt to growing production needs while maintaining compliance and reliability.

Get in Touch Today

Get in touch today to explore how our dairy processing solutions can elevate your production efficiency and product quality.