Process solutions for dairy products

We deliver efficient, hygienic, and scalable processing systems tailored to the specific needs of the dairy industry.

Dairy Process Solutions

Process Solutions for Dairy Products

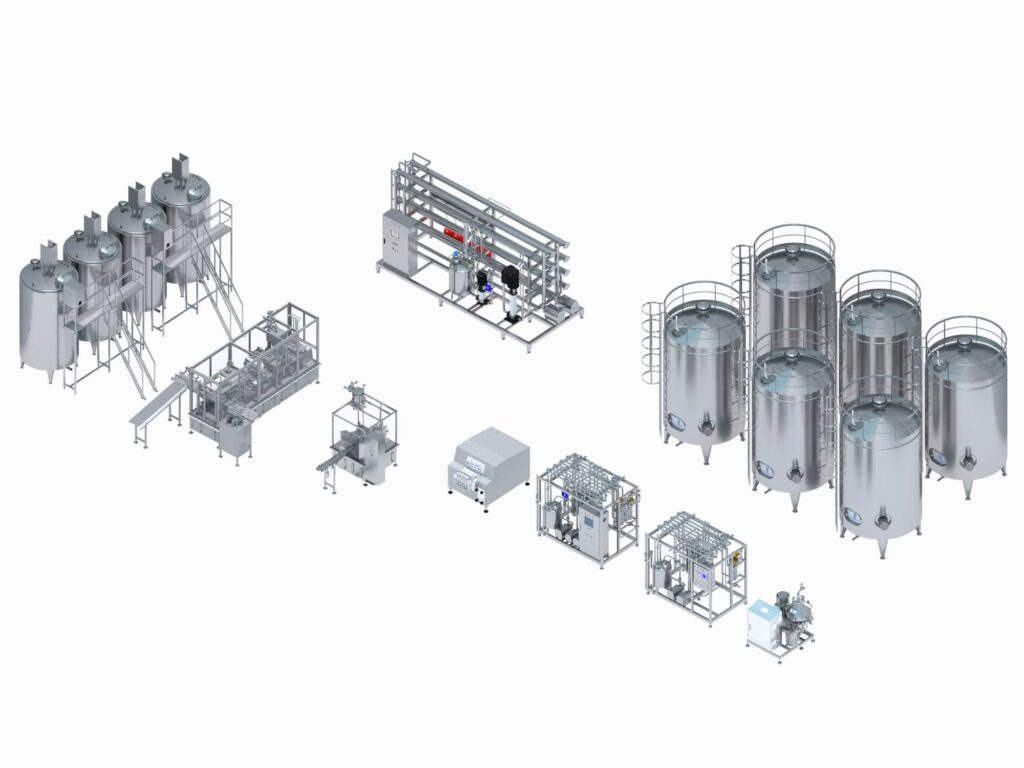

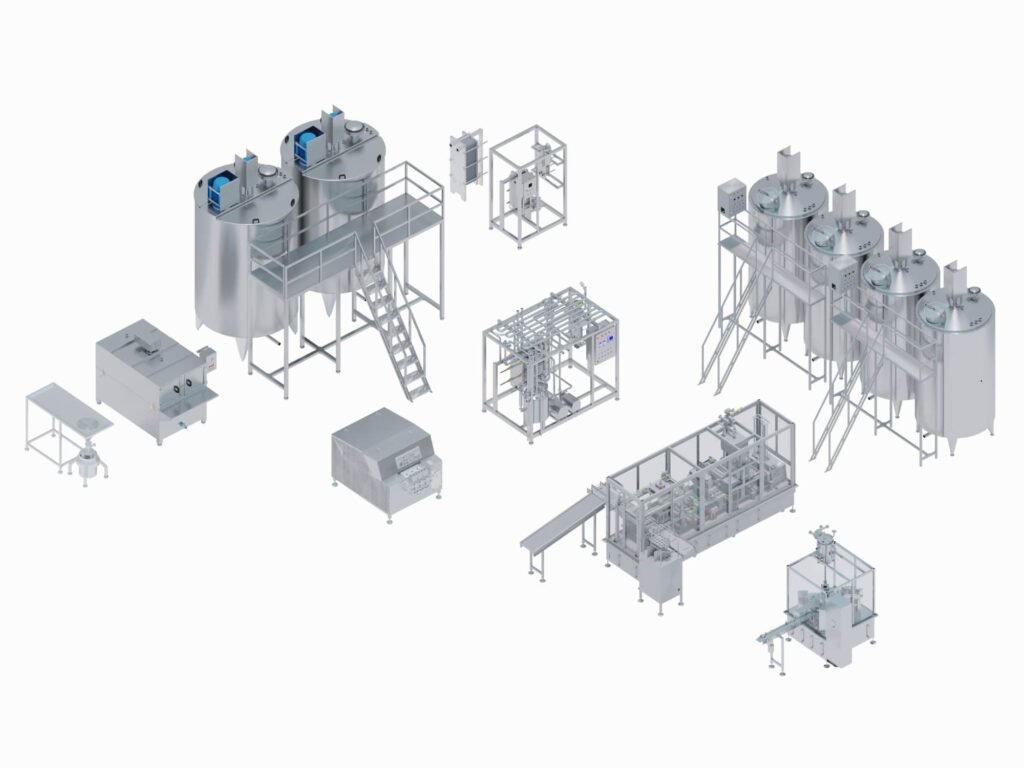

ProTrus offers innovative, end-to-end process solutions for the dairy industry, including milk, yogurt, cheese, cream, ayran, and kefir production. Designed to meet the highest hygiene standards, our systems reduce energy use, enhance product safety, and integrate seamlessly into Industry 4.0 environments.

Contact Form

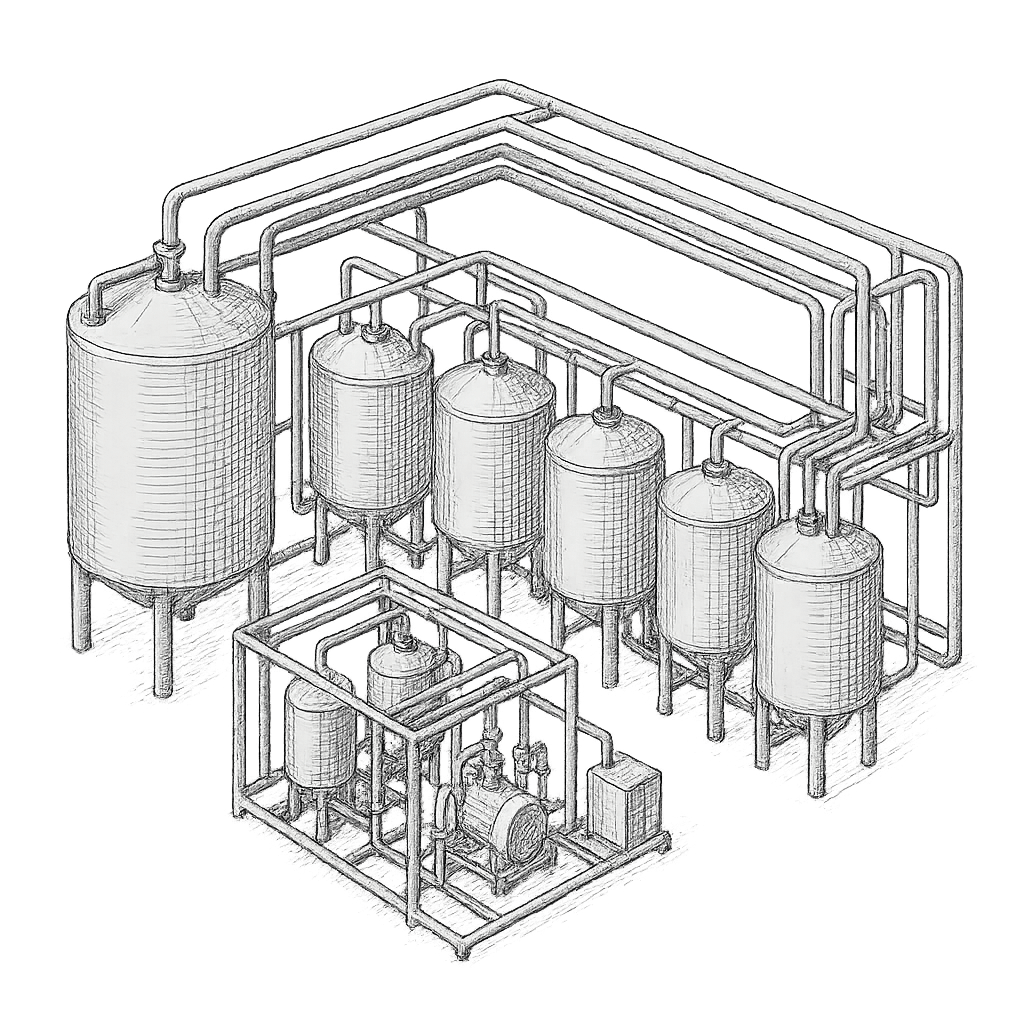

Comprehensive Dairy Processing Systems

We provide scalable, automated processing lines that meet the specific needs of modern dairy manufacturers.

Comprehensive Dairy Processing Systems

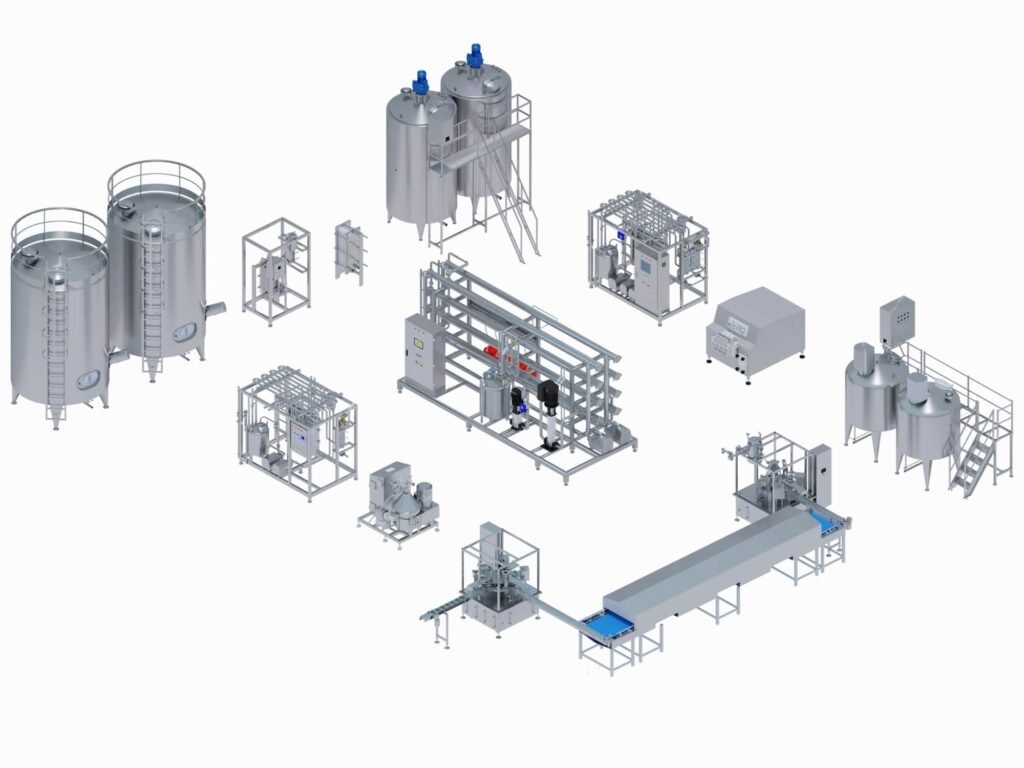

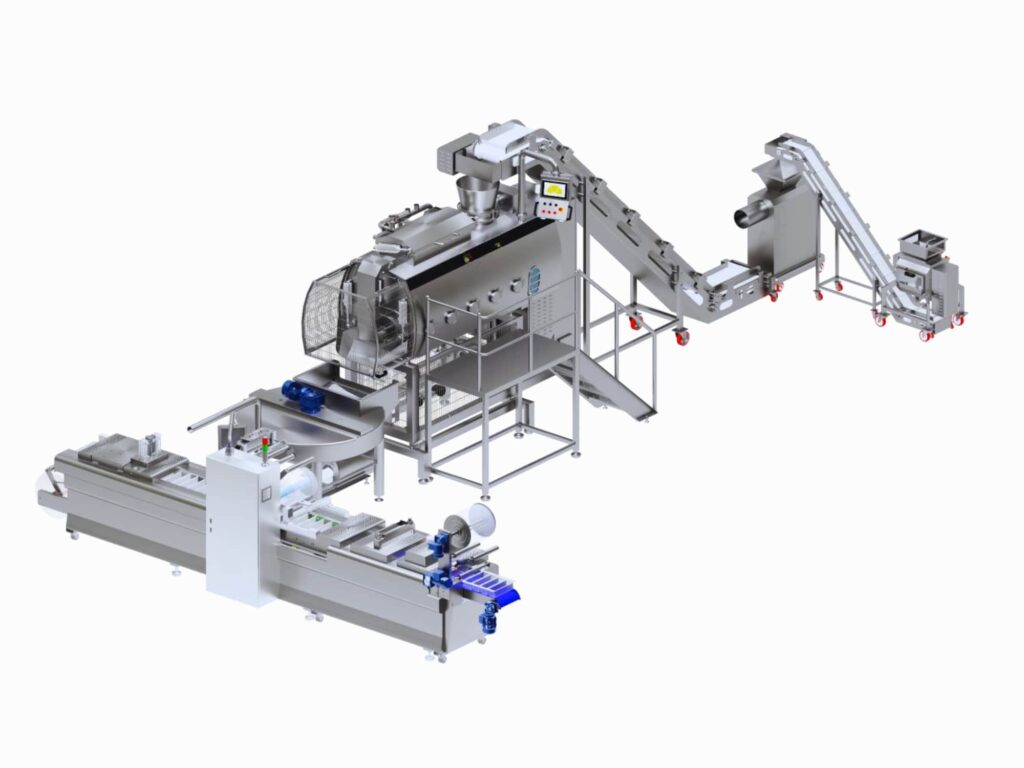

We provide scalable, automated processing lines that meet the specific needs of modern dairy manufacturers. Milk standardization and pasteurization, yogurt fermentation and filling, as well as cheese curd processing with integrated CIP (Clean-in-Place) systems, are all part of our core offering.

Designed for Operational Excellence

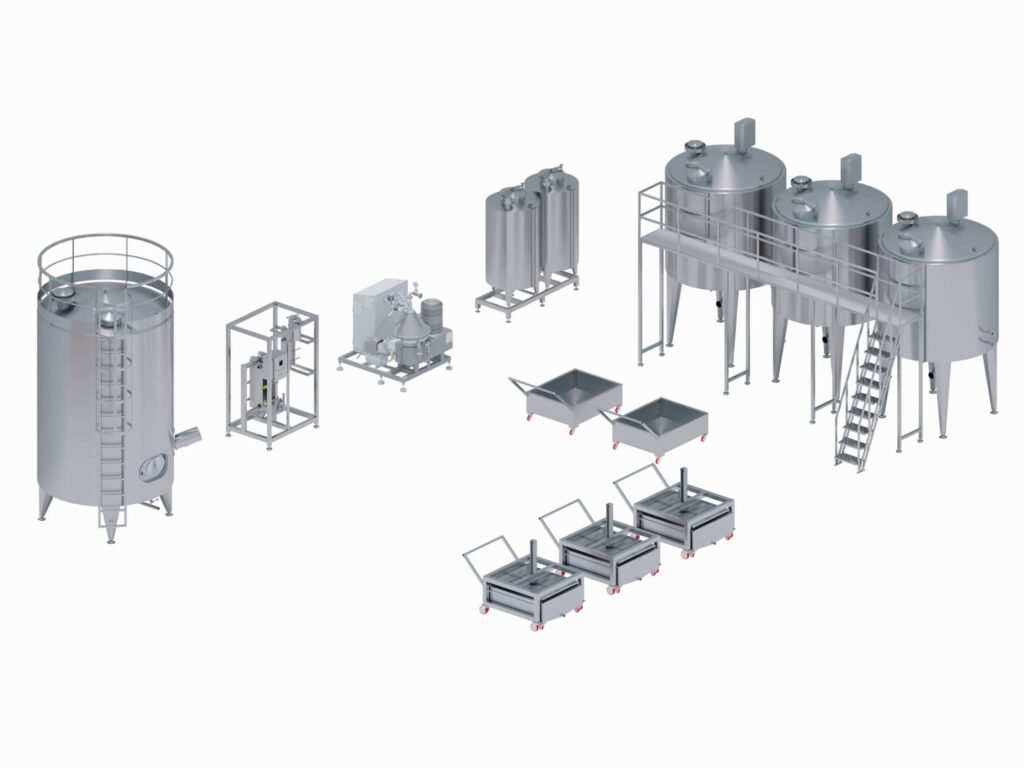

At ProTrus, we understand the critical importance of efficiency, hygiene, and precision in dairy production. Our solutions are developed with these principles at the core, helping manufacturers improve productivity while meeting the highest food safety standards. Every component of our processing systems—from tanks and homogenizers to pasteurizers and filling machines—is designed for long-term reliability and low maintenance.

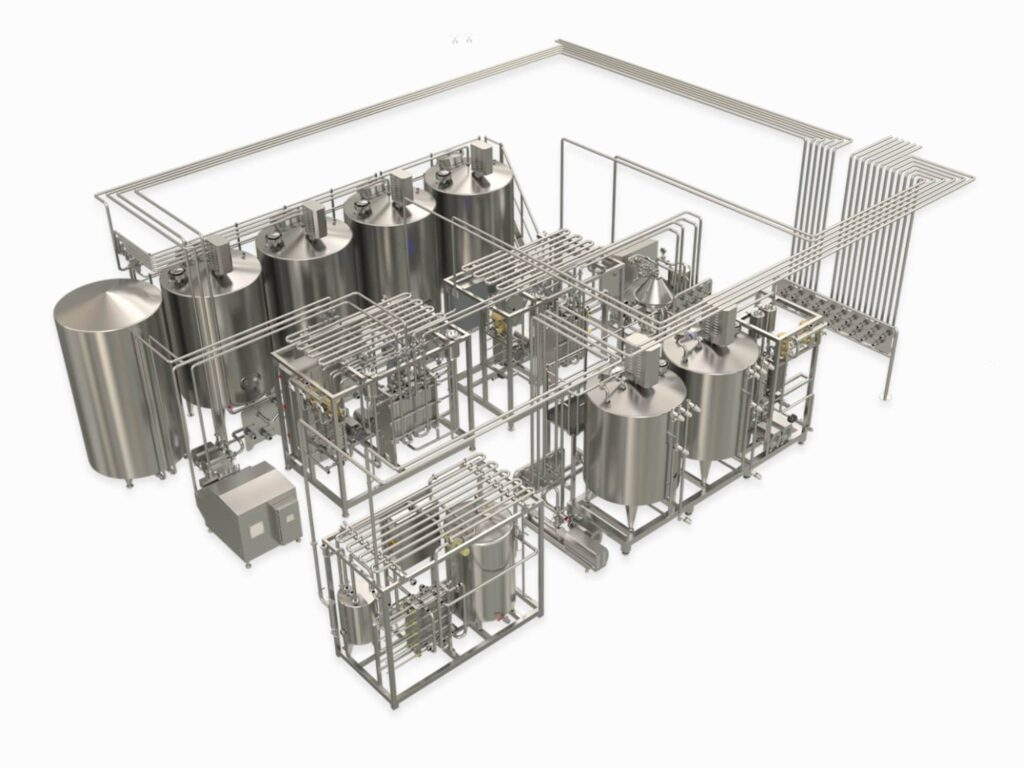

We implement smart automation technologies that reduce labor requirements and eliminate production downtime. Systems can be fully integrated with SCADA or MES platforms to provide real-time monitoring, remote control, and production analytics. This allows dairy producers to manage processes with greater visibility and make data-driven decisions that optimize overall performance.

Our hygienic design approach minimizes the risk of contamination. All equipment is built using food-grade stainless steel and incorporates features such as sloped surfaces, easy-access panels, and sanitary piping. These elements support quick cleaning and prevent residue accumulation, contributing to both product quality and compliance with global food safety regulations.

Flexibility Across Product Categories

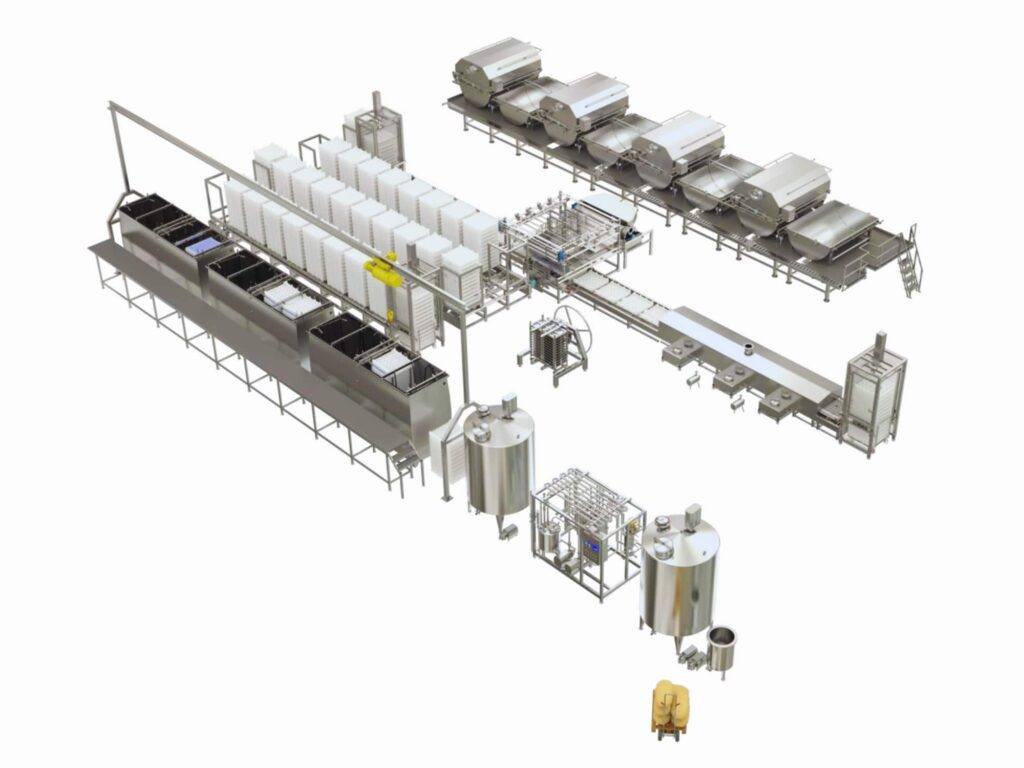

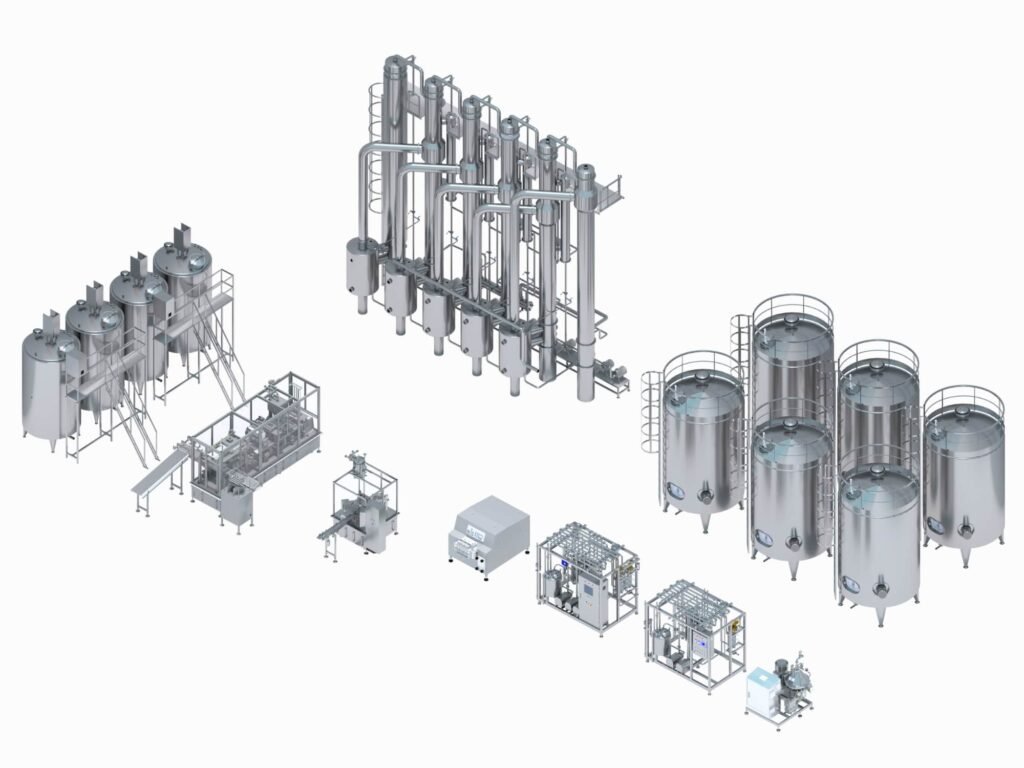

ProTrus systems are tailored to meet the diverse demands of the dairy industry. Whether you are processing fluid milk, fermented drinks, soft or hard cheeses, our modular systems adapt to different product types and volumes. For example, our yogurt lines can be configured for stirred or set yogurt and are compatible with fruit or flavor injection systems. Our milk lines handle everything from standardization to UHT treatment, ensuring extended shelf life without compromising nutritional value.

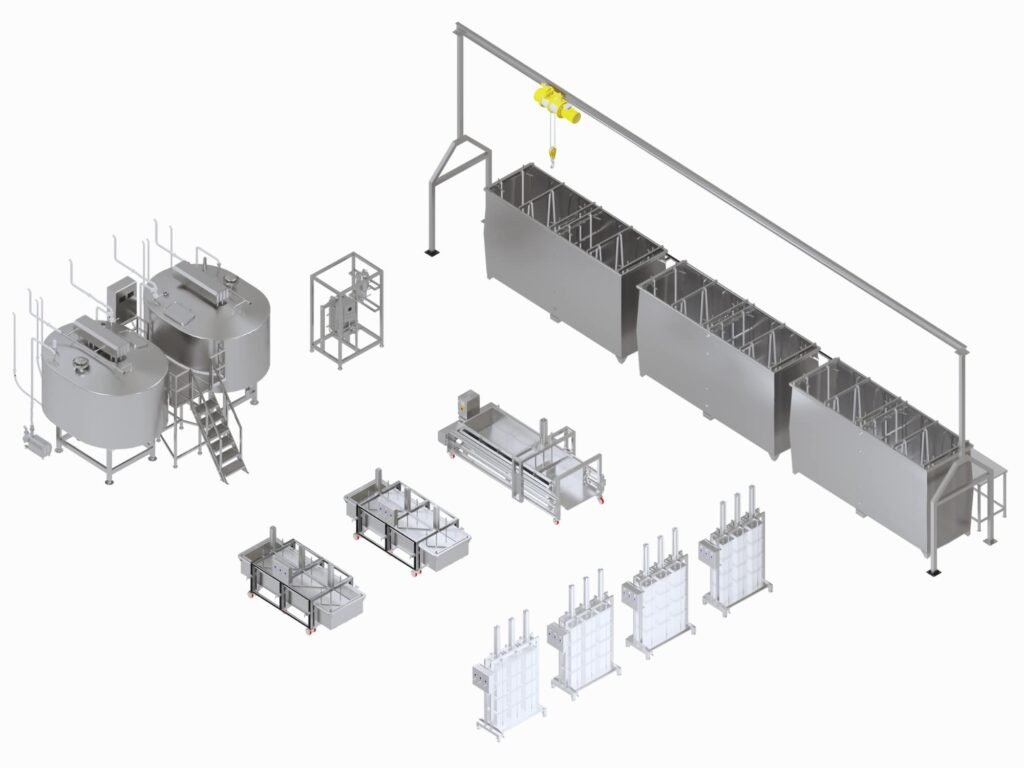

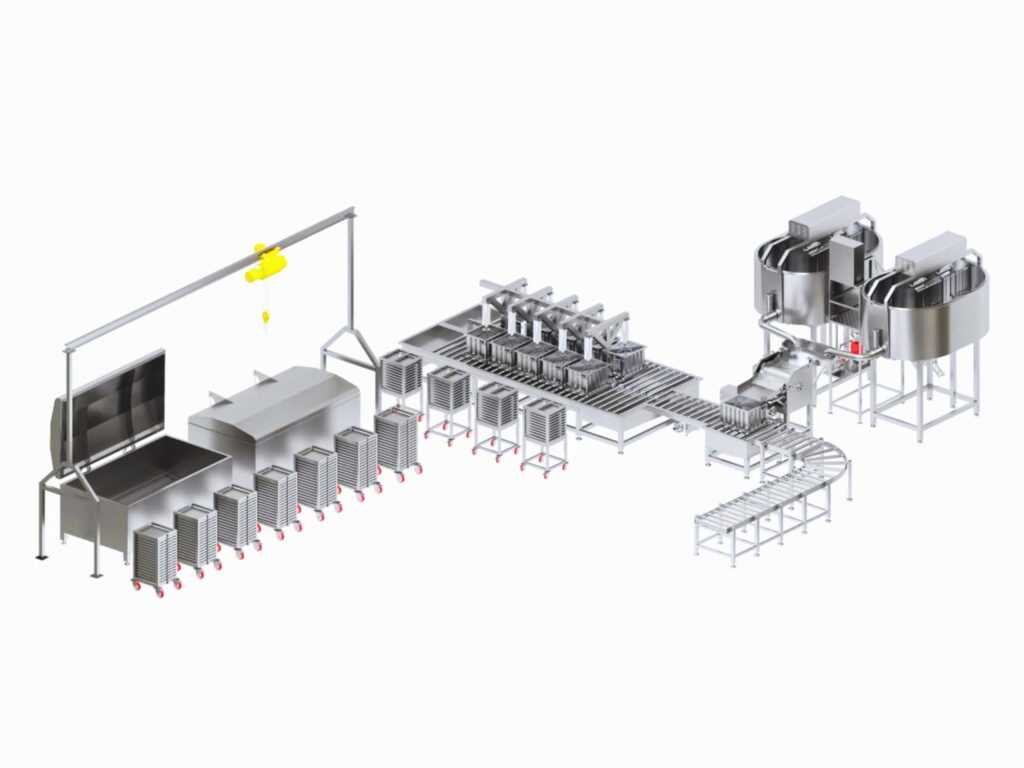

For artisanal and industrial-scale cheese production, we offer customized solutions that include curd cooking, draining, cutting, pressing, and salting. Our equipment ensures uniform texture, accurate portioning, and consistent product quality, which are crucial for branding and market competitiveness.

Fermented beverages like ayran and kefir also benefit from our specialized lines. These systems support controlled fermentation, cooling, and aseptic filling, which are essential for preserving live cultures and achieving desired taste profiles.

Energy Efficiency and Sustainability

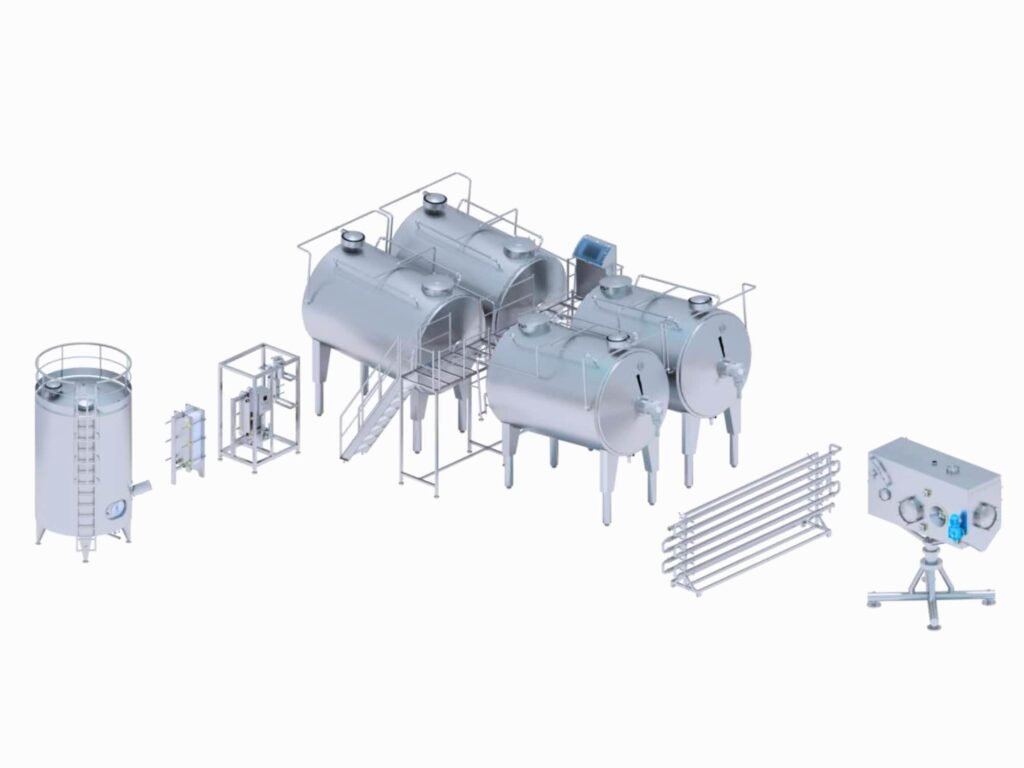

Energy efficiency is no longer optional—it’s a requirement in modern food production. ProTrus dairy systems are designed with sustainability in mind. We use advanced heat recovery systems, variable frequency drives, and optimized flow control to minimize electricity and water usage. Our pasteurization units, for instance, are built to reuse heat from the outgoing product to preheat incoming batches, reducing energy consumption significantly.

Additionally, our CIP systems automate the cleaning cycle, drastically reducing water and chemical usage compared to manual methods. This not only lowers operational costs but also supports environmental compliance and corporate sustainability goals.

By using closed-loop systems, we also help prevent product and ingredient waste, while ensuring full traceability across the production chain. This is especially important in dairy operations, where temperature, pH, and microbial stability must be tightly regulated.

Global Expertise, Local Support

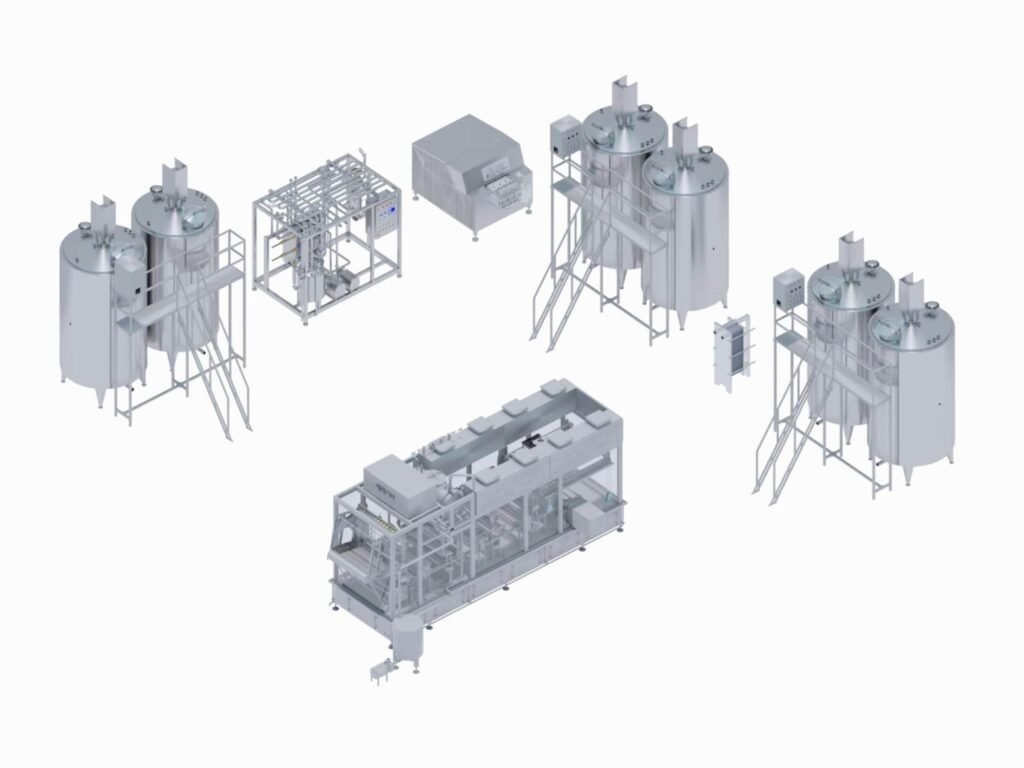

ProTrus has successfully commissioned dairy processing plants on five continents. With engineering teams based in the US, Europe, MENA, and Asia, we provide not only cutting-edge technology but also fast, localized support for installation, training, and after-sales service. We understand the logistical and regulatory differences across markets and tailor our solutions accordingly.

Our CE-marked and ISO 9001-certified systems ensure compliance with global quality standards. In every project, we provide detailed documentation, operator training, and validation protocols to ensure a seamless production launch. Whether you’re upgrading an existing facility or building a greenfield plant, we offer complete support from design to commissioning.

Future-Proof Your Dairy Production

As consumer expectations shift and food safety regulations become stricter, dairy manufacturers need solutions that are not only efficient today but scalable for tomorrow. ProTrus helps you future-proof your production with systems that are easy to upgrade, expand, and digitize. Our team works closely with your engineers to develop factory layouts, select optimal machinery, and integrate automation tools that ensure long-term success.

From small-scale producers to multinational dairy brands, we provide the same level of engineering precision and customer focus. Let us help you transform your production into a model of modern efficiency, hygiene, and innovation.

Get in Touch Today

Get in touch today to explore how our dairy processing solutions can elevate your production efficiency and product quality.